07 | 2010 – A small step at the planning stage, large cost-savings in production: Cleaning technologies of the Fraunhofer FEP bring convincing benefits

The Fraunhofer FEP will be presenting systematic cleaning technology solutions for industrial processes at the leading international fair for cleaning in production and maintenance processes “parts2clean” in Stuttgart

Cleaning. For many an everyday chore. However, tiny amounts of contamination invisible to the eye can cause serious damage to industry and harm to health. The retail sector has to regularly deal with recalls of faulty products. Recent news reports about nutrient solutions contaminated with bacteria demonstrate the importance of accurately monitoring sterilization processes. This is not only costly and bad for the reputation of the manufacturer, but can present risks for consumers.

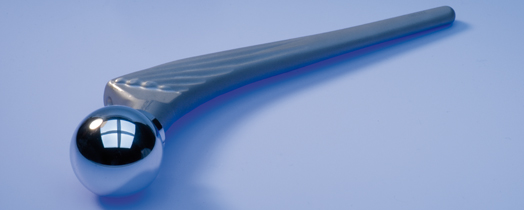

In the same way that a suction cup does not stick to greasy or dusty tiling, coatings will peel off surfaces if these are not thoroughly cleaned beforehand. The peeling off of the coating impairs not only the outward appearance, but is often accompanied by a loss of functioning of the whole product. An important step in the value creation is hence to remove dust, grease, rust and other contaminants from the starting materials.

The Fraunhofer Institute for Electron Beam and Plasma Technology FEP in Dresden develops equipment and technologies for coating and modifying raw materials, semi-finished products, and components. The importance of effective surface pretreatment has been long known to the scientists at the Fraunhofer FEP. Frank-Holm Rögner, who has been working on cleaning technology at the Fraunhofer FEP for many years, is aware of the difficulties for industry: “Although the cost of cleaning processes is often up to 30% of the total production costs, even major companies often do not have an adequate strategy for optimizing the cleaning steps. Costs and material expenditure can be drastically reduced by training and educating employees and by using cleaning technologies at the start of the value creation chain.“

A surface that is clean is not necessarily sterile. A sterile surface in turn is not necessarily clean. Both aspects are however extremely important in the medical area. For this reason, Fraunhofer FEP researchers are also actively developing methods for sterilization and disinfection using low-energy electrons. These methods are important for freeing sensitive products such as medical products, pharmaceutical and food packaging, and medical instruments from germs in a gentle, efficient, and reliable way. Besides their electron beam technology and their wet-chemical cleaning plants and state-of-the-art plasma-etching methods, the institute possesses its own analytical department and biomedical laboratory unit. Thus, the effectiveness of cleaning can be immediately tested from a materials and microbiological point of view.

The Fraunhofer FEP has extensive know-how here and is developing comprehensive solutions in conjunction with other institutes as part of the Fraunhofer Cleaning Technology Alliance. The diverse expertise of the partner institutes means that supra-sector and supra-process cleaning solutions can be independently developed. In order for manufacturing industry to directly acquire this expertise, the Fraunhofer Alliance offers topic-related training courses. Since 2009 a seminar for engineers and production supervisors covering key cleaning issues in industrial practice has also been offered. [MM]

Last modified:

Fraunhofer Institute for Electron Beam

Fraunhofer Institute for Electron Beam