16 | 2016 – Applying electron beams to 3-D objects

The Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP now has the technological means of applying electron beams very flexible to 3-D objects through use of its new miniaturized electron beam source of the Swiss company ebeam by COMET.

Electron beams are useful in many different applications. They reliably sterilize seed, can weld small structures precisely and reliable, and cure decorative paint. Usually this involves either planar, flexible, or slightly curved surfaces. However, applying electron beams homogeneously to 3-D objects of any size or shape has not been so simple up to now.

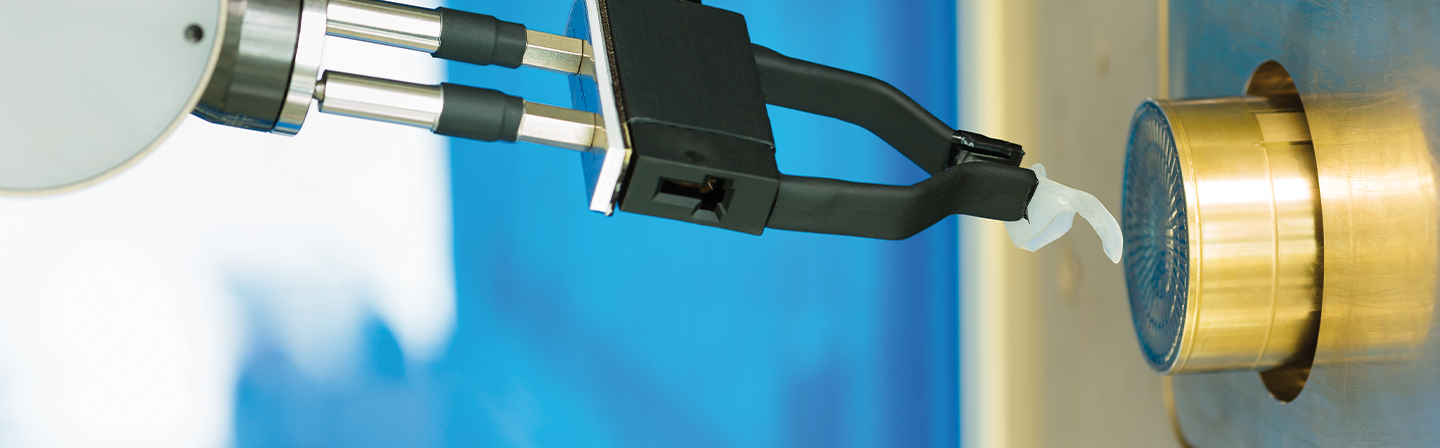

Scientists at Fraunhofer FEP have now elegantly combined a miniaturized electron beam source with a six-axis robotic manipulator in order to be able to treat substrates with complex shapes as well as spherical objects, for example.

“The electron beam source remains stationary in this process”, explains Javier Portillo, a scientist at Fraunhofer FEP. “The manipulator rotates the objects within the irradiation zone in a way, that the surface will be treated homogeneously. This creates the maximum degree of freedom when applying an electron beam to a 3-D-object.”

Normally several electron beam sources are needed to treat 3-D objects. Homogeneous application does not take place reliably everywhere in this process. The process of multiaxial moving the object within the electron treatment zone can hereby generate advantages. The application of electron beams to optical components is also conceivable. These primarily involve hydrophilic surfaces found in a wide variety of applications, such as safety glasses with antifogging coatings, diffusing screens and lenses, and anti-condensation coatings for air conditioners and sensors in medical engineering. Scientists can apply the new technology to develop customized processes for its industrial clients that meet specific demands – including being able to treat 3-D objects with various geometries – to suit even the most diverse existing production lines.

The symbiosis of an electron beam and robotic handling can make production processes more effective and economical.

Among other places, the new technology will be presented by Javier Portillo at the 12th "Ionizing Radiation and Polymer Symposium (IRAP)" taking place on the Giens Peninsula in France from September 25th – 30th, 2016.

Talk

Electron Beam Curing of Acrylic Elastomers for Medical Products

September 26th, 2016, 11:30 a.m., Session XIII: Surface Treatment

Presenter: Javier Portillo, Fraunhofer FEP

Fraunhofer Institute for Electron Beam

Fraunhofer Institute for Electron Beam