Multimodal X-ray and hyperspectral thin-film nano-material evaluation and quality imaging – nanoQI

nanoQI creates an industrial-scale, real-time technology for in-line characterization and quality control of nanoscale thin film properties on large surfaces, based on hyper-spectral imaging.

Since 2020, the Fraunhofer FEP has been coordinating the EU project »nanoQI«. The aim of the project is to establish a technology for quality control of thin film properties such as layer thickness, density, and chemical composition on large substrate surfaces on an industrial scale. This technology is crucial for optimizing and further developing modern thin film technologies in terms of material quality, reproducibility, productivity, and the technology transfer of these processes to industry.

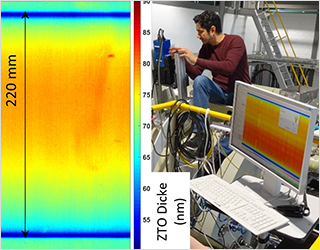

To achieve this goal, X-ray measurement methods such as X-ray reflection (XRR) or X-ray diffraction (XRD) are combined with hyperspectral imaging (HSI) in the VIS-NIR spectral range and integrated into various process systems at the three partner sites Fraunhofer FEP, Fraunhofer IAP, and TNO Eindhoven. The necessary components, such as XRD/XRR prototypes (Bruker AXS), spectral cameras and optics (Norsk Elektro Optikk, NEO), HSI light sources (Fraunhofer IWS), as well as the software for HSI data acquisition, evaluation, and visualization (Fraunhofer IWS, NEO, Fraunhofer FEP), were developed in close cooperation within the consortium.

Machine learning models are being developed for in-line quantification and visualization of layer properties using HSI, which will be trained initially with the results of XRD/XRR measurements. After implementation of the models in the HSI software at the systems, it can independently determine layer properties from the generated HSI raw data during the coating process for process control and monitoring.

In the final phase of the project, the demonstration and industrial validation of the methods and technologies developed so far is the main focus. The nanoQI solutions will be used under realistic operating and production conditions to develop strategies for upgrades and optimizations, but also for detailed cost-benefit analysis to pave the way for commercial exploitation.

For example, at Fraunhofer FEP, in-line HSI quality control of <100 nm thin barrier and contact layers, deposited by roll-to-roll magnetron sputtering on polymer films up to 600 mm wide and several hundred meters long, is being implemented. For oxide layers on PET, a layer thickness accuracy of a few nanometers with a spatial resolution of less than 1 mm and a web speed of several m/min has already been demonstrated.

Fraunhofer Institute for Electron Beam

Fraunhofer Institute for Electron Beam