Paving the way for new ultra-thin glass application – unique process chain for processing ultra-thin flexible glass available

The processing of ultra-thin glass requires specialized handling to avoid glass breakage during production. Until now, this has been a major obstacle for the entry of this innovative material into new applications. Therefore, a unique process chain for ultra-thin glass processing has been implemented at Fraunhofer FEP: starting with adapted cleaning processes up to the final inspection. The results have been funded within the project CUSTOM (grant no. AiF 21708 BR) by the German Federal Ministry of Economics and Climate Protection BMWK and the project Glass4Flex (grant no. 13N14615) funded by the German Federal Ministry of Education and Research BMBF. Particular attention was paid to the evaluation of the influence of process parameters on the strength and reliability of the coated glass. The process chain and results of the projects will be presented at the V2023 conference, September 18 – 21, 2023, in Dresden.

With the market launch of foldable displays, flexible glass entered mass production. Apart from that, ultra-thin glass with "thicknesses" of less than 0.1 mm is used in optics or microelectronics, but also in the consumer and automotive industries, e. g. for touch surfaces. Here, the glass can be beneficial due to its excellent surface properties such as low surface roughness, high transparency and scratch resistance in combination with its flexibility and hardness.

To establish ultra-thin glass as an alternative to polymer webs for applications beyond foldable displays, adapted production processes must be developed. Emphasis is placed on avoiding cost-intensive production downtimes due to mechanical failure of the glasses. Indeed, the use of this innovative substrate material has been limited by the high demands of the processes by now. In addition, knowledge about handling and functionalization is not generally available.

End-to-end process line for processing ultra-thin glass

For more than ten years, Fraunhofer FEP has been involved in the processing of ultra-thin glass, especially in the handling and the development of coatings.

Besides the coating process itself, cleaning and handling as well as defect detection in the uncoated and coated glass are essential for subsequent usability of the flexible glass. A publicly accessible technology platform for the consistent implementation of these steps did not yet exist.

This is the starting point for the joint research project Glass4Flex. In this project, new process technologies were developed to pioneer flexible glass applications for next-generation optical and/or electrical applications. Developers of such systems can now use the platform at Fraunhofer FEP.

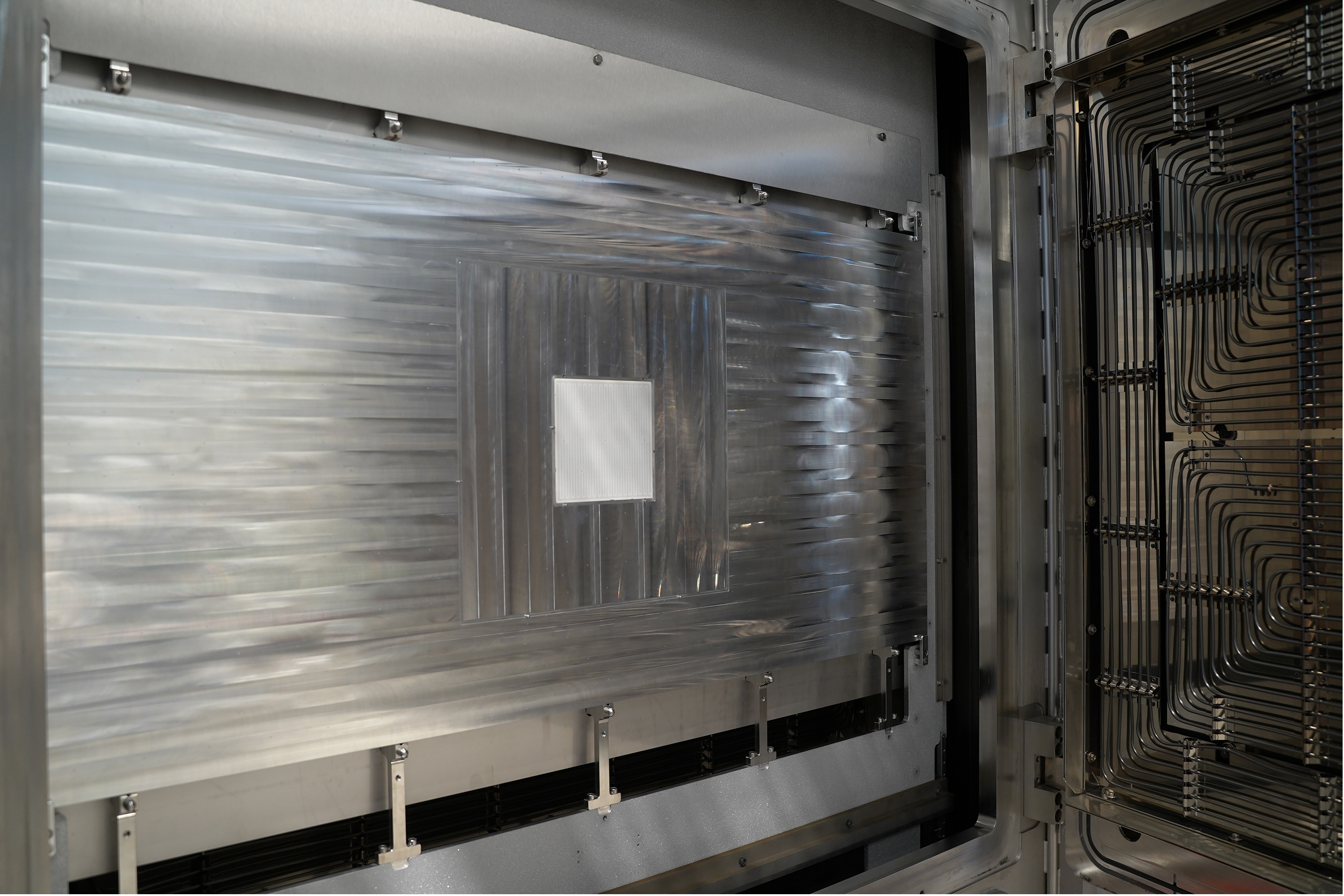

Project manager Kerstin Täschner from Fraunhofer FEP explains the status achieved shortly before the end of the project: "Together with our partners, we have now set up a process chain at Fraunhofer FEP that is unique in its kind under cleanroom conditions. We have a handling line for flexible glass down to a minimum thickness of 30 µm on an area of 600 × 1200 mm². The process chain completes our vertical inline coating system ILA 900. It allows us to use and share our many years of experience in coating thin glass and the know-how gained from collaboration with all major glass manufacturers as well as from projects such as CUSTOM throughout on a pilot scale."

The process line includes an ultrasonic wet cleaning machine of the SCHMID Group, in which glass sheets can be cleaned inline. The researchers also have a white light interferometer of the Gesellschaft für Bild- und Signalverarbeitung (GBS) mbH at their disposal to monitor the cleaning and coating quality of the glass.

For further handling of the thin glass substrates of the project partner SCHOTT AG, a new transfer system of the Adenso GmbH was also installed. Under clean room conditions, the substrate can be transported contact-free by air cushion floating on a mobile cart. The electrostatic holder (so-called E-Chuck) of the ProTec® Carrier Systems GmbH is already installed on this cart. The E-Chuck is then brought into the vertical position and ensures full-surface contact of the thin glass to the carrier in the coating and plasma treatment processes. This guarantees homogeneous thermal conditions with homogeneous mechanical stress and without any shadowing effects.

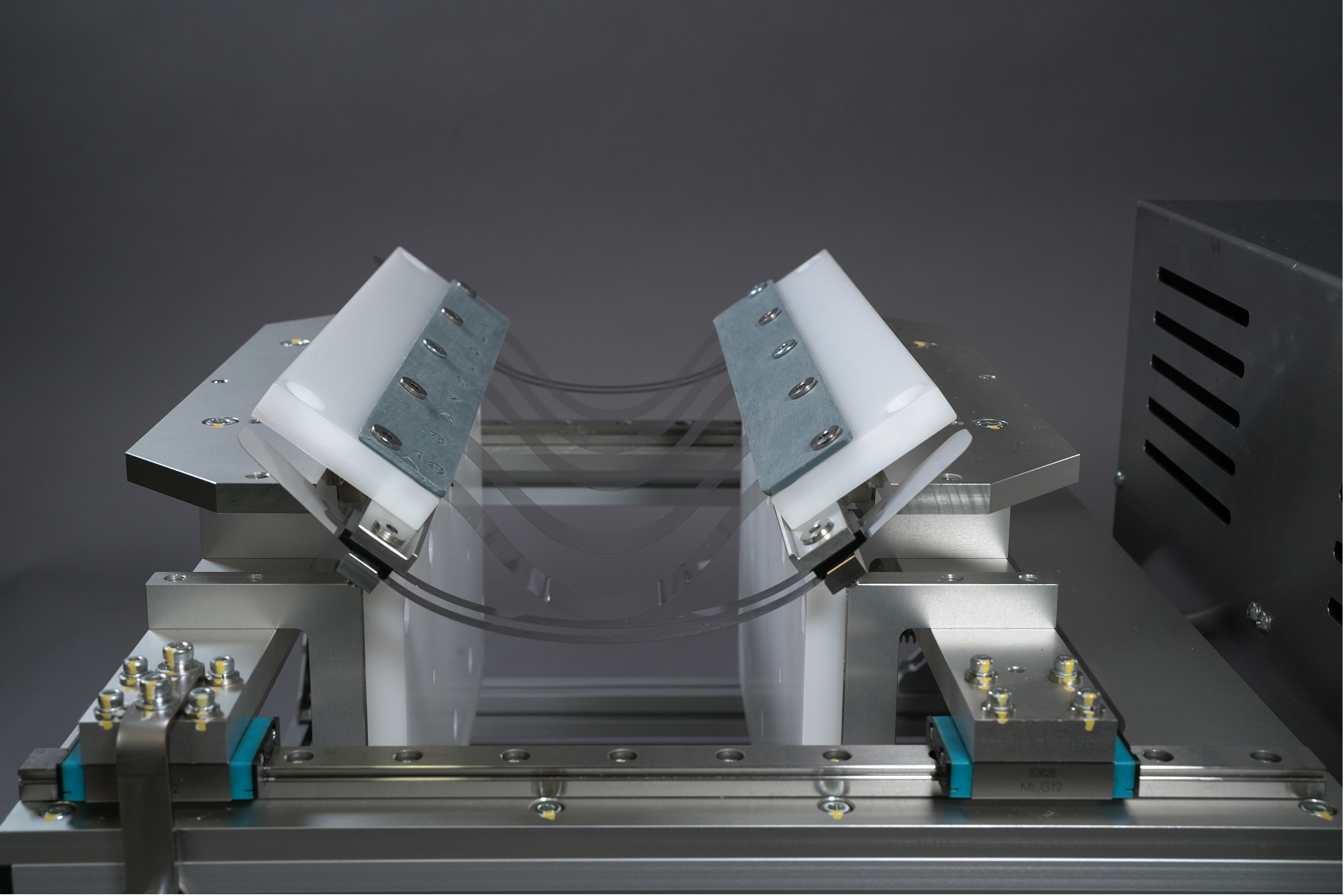

After coating, reliability tests of the ultra-thin glass sheets can be carried out. Bayflex Solutions provided bending test equipment for this purpose as part of the CUSTOM project (YUASA U-Shape Folding and YUASA Clamshell Folding).

With the aid of the equipment provided, deeper insights into the edge strength and fatigue behavior of flexible glass were achieved. Together with researchers of the Fraunhofer Institute for Microstructure of Materials and Systems IMWS, Fraunhofer FEP researchers carried out extensive tests for this purpose. During these tests, the influence of selected coating and separation processes on the mechanical properties was investigated. The results can now be used to estimate parameter fields for the reliable handling of flexible glass more accurately, e. g., minimum winding radii before and after coating. By this, strength changes can be considered during processing. This increases the production yield because downtimes are avoided.

The future of thin glass processing

With the unique process line realized in the project Glass4Flex and the results from the project CUSTOM, scientists at Fraunhofer FEP are now able to safely handle and reliably process ultra-thin glass while taking thin film stress and glass strength into account. As of now, the researchers at the institute offer the new process capabilities for customer-specific projects ranging from coating and layer stack development to process adaptation for special customer requirements. In addition, the handling line is available as a technology platform, e. g. for feasibility studies and the development of innovative applications. The integration of lamination processes and process transfer up to pilot production is now also possible in individual projects.

The researchers will be present at the V2023 conference, September 19–20, 2023, at the Dresden Congress Center. They are available for further discussion and explanation of the process chain and the findings related to the projects CUSTOM and Glass4Flex.

About the projects

CUSTOM – Investigation of the material behavior of ultra-thin flexible glass in layered composites

Funded by: Federal Ministry of Economic Affairs and Climate Action

Grant number: 21708 BR

Duration: 01.03.2021 - 30.08.2023

Project partner: Fraunhofer IMWS

Companies from the advisory committee with outstanding contribution to the project:

- SCHOTT AG

- 3D-Micromac AG

- MDI Advanced Processing GmbH

- Bayflex Solutions

- GfE GESELLSCHAFT FÜR ELEKTROMETALLURGIE MBH

Glass4Flex – New process technologies paving the way for flexible glass applications in optical systems

Funded by: German Federal Ministry of Education and Research

Grant number: 13N14615

Duration: 2019 - 2023

www.photonikforschung.de/projekte/optikkomponenten/projekt/glass4flex.html

Project partner

- SCHOTT AG, www.schott.com

- SCHMID Group, www.schmid-group.com

- Gesellschaft für Bild- und Signalverarbeitung (GBS) mbH, www.gbs-ilmenau.de

- Adenso GmbH, www.adenso.solutions

- ProTec® Carrier Systems GmbH, www.protec-carrier.com

Further publications on the topic

- W. Langgemach, G. Lorenz, K. Täschner, J. Neidhardt: “Optische Schichten und ihr Einfluss auf die Belastbarkeit flexibler Gläser”, Vakuum in Forschung und Praxis 35 (2023) 4, DOI:10.1002/vipr.202300803,

S. 28-33

- W. Langgemach, K. Täschner, T. Preußner, J. Neidhardt: „Aspects of durability and handling of vacuum coated ultra-thin flexible glass”, LOPEC 2023, München

- W. Langgemach, G. Lorenz, K. Täschner, F. Naumann, T. Preußner, M. Ott “Processing flexible glass – thin film stress and its influence on glass durability”, IRSP 2023, Bad Schandau

- K. Täschner, W. Langgemach, T. Preußner, J. Neidhardt: „Processing of ultra-thin flexible glass in sheet-to-sheet vacuum coating”, 18th International Conference on Plasma Surface Engineering PSE, September 12 – 15, 2022, Erfurt

Fraunhofer FEP at V2023

September 18 – 21, 2023, International Congress Center Dresden, Germany

https://efds.org/en/v2023/

Exhibition: booth number A4

Conference talks

Monday, 18.9.2023

4:00 pm, at SBS Metalltechnik GmbH

Electrical design and control concepts of sputter coating equipment

Michiel Top, Fraunhofer FEP

Tuesday, 19.9.2023

10:30 am, Room 4 & 5

Keynote: Plasma and surface technologies for energy applications and sustainability

Prof. Dr. Elizabeth von Hauff, Fraunhofer FEP

11:20 am, Room 3, Session: Coatings for Energy

Vacuum Coating Technologies for Silicon-based Next Generation Anodes for

Lithium-Ion Batteries

Dr. Stefan Saager, Fraunhofer FEP

03:10 pm | Room 5, Session: Coatings for Optics

Augmented reality displays - a new challenge for large area precision coatings

Dr. Daniel Glöß, Fraunhofer FEP

Wednesday, 20.9.2023

11:20 am | Room 3, Session: Coatings for Energy Technologies

Carbon dioxide conversion in an electron beam sustained atmospheric pressure plasma

Lars Dincklage, Fraunhofer FEP

01:20 pm | Room 3, Session: Innovation with collaborative research

Processing flexible glass – the influence of functionalization on the edge strength and durability of ultrathin glass

Wiebke Langgemach, Fraunhofer FEP

01:40 pm | Room 4, Session: Coatings for Biomedical Applications

Antibacterial coatings for surface hygienization

Linda Steinhäußer, Fraunhofer FEP

Poster

- Optimization of zinc-tin-oxide permeation barrier layers on flexible substrates

Manuela Erhardt, Fraunhofer FEP - Abrasion resistant coatings by roll-to-roll technologies

Stefan Hinze, Fraunhofer FEP - Paving the way for new flexibility - Handling and functionalization of ultra-thin flexible glass in the S2S process chain

Wiebke Langgemach, Fraunhofer FEP - Deposition of removable magnetoresistive layers for the production of powder-based printable sensors

Morris Ott, Fraunhofer FEP - Eddy Current Monitoring in High Temperature Vacuum Environment

Thomas Preußner, Fraunhofer FEP - Setup and Applications of Large Area Flash Lamp Annealing

Thomas Preußner, Fraunhofer FEP - Thin Film Technologies for Energy Saving Solutions in Architecture

Cindy Steiner, Fraunhofer FEP

Fraunhofer Institute for Electron Beam

Fraunhofer Institute for Electron Beam