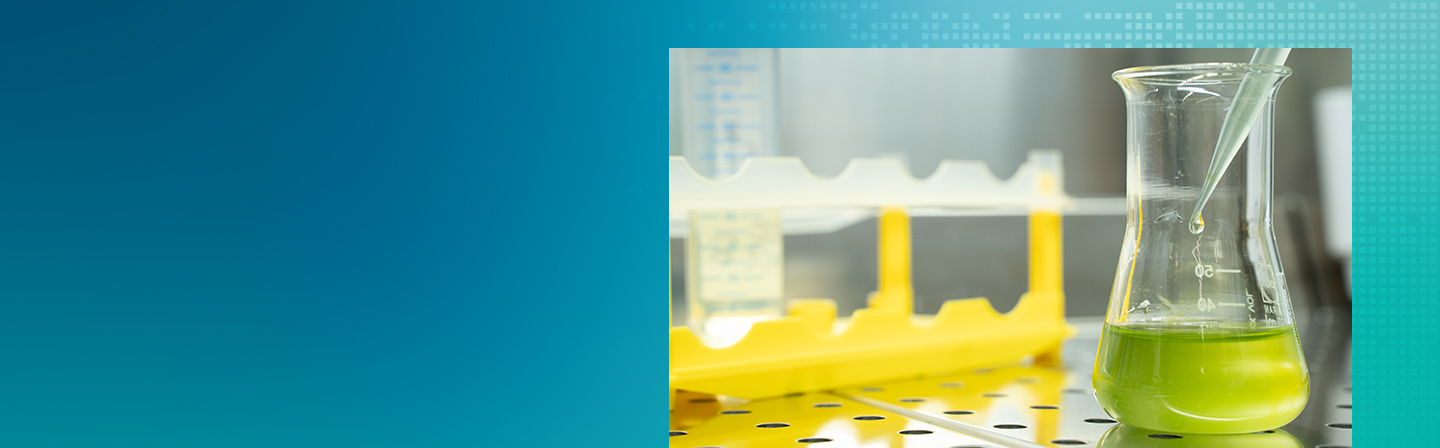

Fraunhofer FEP presents a novel hybrid technology that combines a low-energy electron beam source with a bioreactor. The plant, which has now gone into operation, is the first practical implementation of this innovation. The result is a flexible, scalable platform that opens up new possibilities for biotechnological applications – from resource-efficient metal extraction to sustainable environmental technology. The new technology can strengthen the National Bioeconomy Strategy by optimizing bioprocesses and making biological resources more efficient to use.

more info Fraunhofer Institute for Electron Beam

Fraunhofer Institute for Electron Beam