14 AMI

Joint project module development for 14 Angstrom lithography in chip production

Funded by:

Bundesministerium für Bildung und Forschung

Funding reference: 16MEE0365

Duration: 01.05.2023 -30.04.2026

Joint project module development for 14 Angstrom lithography in chip production

Funded by:

Bundesministerium für Bildung und Forschung

Funding reference: 16MEE0365

Duration: 01.05.2023 -30.04.2026

Development of living building materials via in situ carbonate mineralization using microorganisms.

Funded by:

Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung e. V.

This work was supported by the Fraunhofer InternaI Programmes

Funding reference: SME 840 131

Duration: 2021 - 2025

Development of biogenic calcium carbonate hemp building materials produced by microorganisms

Boost of organic solar technologies for European radiance

Funded by:

Europäische Union; Horizon 2020

Funding reference: 952911

Duration: 01.09.2020 - 28.02.2027

Converting Facilities Network for accelerating uptake of climate neutral materials in innovative products

Funded by:

HADEA European Health and Digital Executive Agency

Funding reference: 101092347

Duration: 01.01.2023 - 31.12.2025

Increasing the cooling capacity through the use of additively manufactured porous copper structures

Funded by:

Fraunhofer SME

Funding reference: SME 40-06700

Duration: 01.07.2023 - 30.06.2026

Funded by: Federal Ministry for Economic Affairs and Climate Action

Funding reference: 03EN1084A

Funding framework: 7th Energy Research Program

Duration: 01.11.2023 - 31.10.2026

Project coordinator:

Digitization of materials research on thin-film materials using the example of high-resolution piezoelectric ultrasonic sensors

Funded by:

Bundesministerium für Bildung und Forschung

Funding reference: 13XP5187D

Duration: 01.04.2023 - 31.03.2026

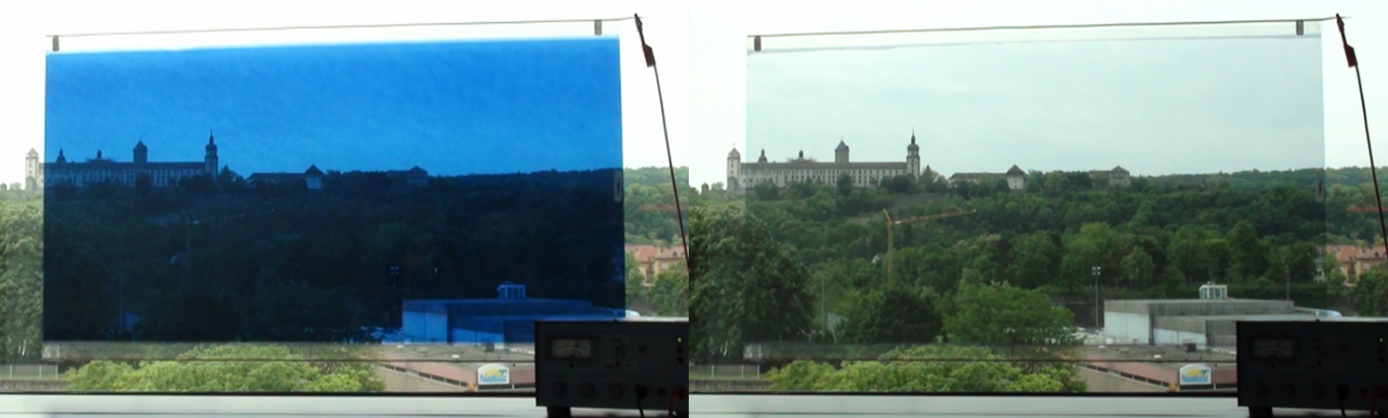

The object of the joint project FLEX-G 4.0 is to develop a cost-effective retrofit solution of innovative switchable films that can be laminated as easily as possible onto already installed windows and contribute to reducing the overall energy transmittance (g-value) of the windows and thus the energy demand of the building.

The main objective of the project is transfer of research results into suitable system designs and manufacturing technologies for large-area electrochromic films to be installed directly on the construction site. Furthermore, robust processes for "easy" on-site application of these films to windows and facades in existing buildings are to be developed. As an integral part of the system design, solutions for mains-independent energy supply and suitable switching parameters and sensor technologies for wireless, automated control of the switching state of the films are to be researched. Another objective includes the demonstration and experimental quantification of the energy saving potential in two operational buildings in the public sector.

For demonstrating and monitoring purposes, it is planned to integrate the retrofit films at an existing building, the 46th Dresden Secondary School, as well as in the newly constructed laboratory building of Fraunhofer FEP. In addition, the Fraunhofer Institutes FEP and ISC will provide teaching materials for science subjects and offer internships for pupils. Involvement in the measurements and evaluation of the results together with the pupils is also planned. This is intended to arouse the interest of the next generation in various technical and scientific professions and also in energy-saving, sustainable technologies and their development.

Contact: Dr. Cindy Steiner

Funded by: Federal Ministry for Economic Affairs and Climate Action

Funding reference: 03EN1048A

Duration: 01.08.2022 - 31.07.2026

Partner:

Mucosal application of RSV antigens to prevent juvenile bronchial asthma

Funded by:

Fraunhofer Cluster of Excellence Immune-Mediated Diseases CIMD

Humic substances for the antiviral functionalization of ecologically sustainable nonwovens for respiratory masks TVH: Use of low-energy electron beam technology for the surface-selective functionalization of textiles with humic substances

Funded by:

Bundesministerium für Wirtschaft und Klimaschutz

Funding reference: 16PS104004

Duration: 01.01.2023 - 31.12.2025

Funded by:

Fraunhofer Cluster of Excellence Immune-Mediated Diseases CIMD

Duration: 01.01.2023 - 31.12.2026

Flexible Perovskite Solar Cells with Carbon Electrodes

More information: www.pearl-project.eu

Funded by:

European Climate, Infrastructure and Environment Executive Agency

Funding reference: 101122283

Duration: 01.10.2023 - 30.09.2026

High-Performance Large Area Organic Perovskite devices for lighting, energy and Pervasive Communications

Funded by:

Europäische Union

Funding reference: 861985

Duration: 01.04.2020 - 30.09.2023

Printed Perovskite Solar Cells for Large Area User Applications

Funded by:

European Union; Horizon Europe

Funding reference: 101147547

Duration: 01.01.2025 - 31.12.2027

PHACTORY - PhotonHub Factory for Next-Generation Photonics Innovation Support: Boosting European Industrial Competitiveness and securing Technological Sovereignty.

Funded by:

HADEA European Health and Digital Executive Agency

Funding reference: 101189537

Duration: 01.01.2025 - 31.12.2028

Photocatalytic conversion of CO2 into glycolate by microbial cell factories using random mutagenesis and artificial intelligence Subtopic: Electron beam mutagenesis

Funded by:

SAB

Funding reference: 3001061328

Duration: 01.06.2024 - 31.05.2027

Joint project: Electrically conductive polymer compound films for electrochemical reactors

Funded by:

Bundesministerium für Bildung und Forschung

Funding reference: 03SF0647B

Duration: 01.10.2021 - 30.09.2025

Increasing biofilter performance in recirculating aquaculture through the biopositive effect of low-energy accelerated electrons

Funded by:

Fraunhofer SME

Funding reference: SME 40-10542

Duration: 01.01.2025 - 31.12.2027

Joint project: revoLect - High-efficiency electrodes with ultralight fabric-based current collectors for lithium-ion batteries. Subproject: Development of vacuum technologies for the productive deposition of columnar silicon layers on fabric.

The aim of the revoLect project is to create novel electrodes with lightweight fabric-based current collectors for lithium-ion batteries (LIB) and significantly increase the specific energy density. The use of pure silicon as the active anode material in combination with a lightweight and adapted fabric structure should help form the basis for this. The aim of Fraunhofer FEP is to develop a process for the advantageous deposition of the silicon on novel fabrics. The layer thickness of the silicon and the fabric structures are to be matched to each other in such a way that an optimum is achieved with regard to the gravimetric energy density of the anode. Another goal is the development of a suitable and economically attractive roll-to-roll evaporation process, with which a layer thickness of at least 9µm silicon can be deposited at a process speed of 1m/min, which corresponds to a capacity of approx. 3 mAh/cm².

Funded by:

Federal Ministry for Economic Affairs and Climate Action

Funding code:

03ETE041A

Duration:

01.09.2022 - 31.08.2025

Project partner:

Antipathogenic protective films for touchscreens Subtopic: Application of flash lamp treatment for the activation of antipathogenic surfaces and the socio-economic considerations involved

Funded by:

SAB

Funding reference: 100631596

Duration: 01.06.2022 - 30.09.2025

Frameless force sensor for process monitoring

Funded by:

SAB/ EU

Funding reference: 3001054135

Duration: 21.03.2024 - 20.09.2026

Key Components for Wireless, Optical and Quantum Communication (WOQ-COMP)

Funded by:

Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung e. V.

Duration: 01.11.2022 -30.10.2025