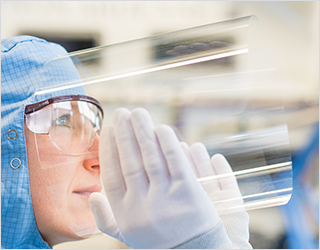

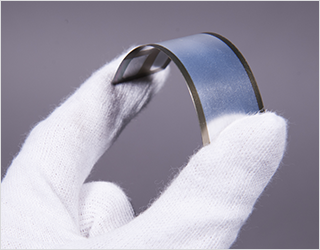

M. Fahland, O. Zywitzki, T. Modes, K. Vondkar, T. Werner, C. Ottermann, M. Berendt, G. Pollack

Roll-to-roll sputtering of indium tin oxide layers onto ultrathin flexible glass

Thin Solid Films

Vol. 669, 2019, p. 56 – 59

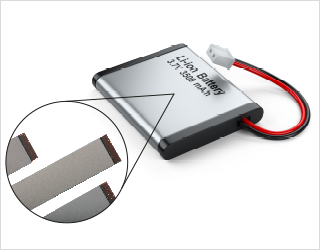

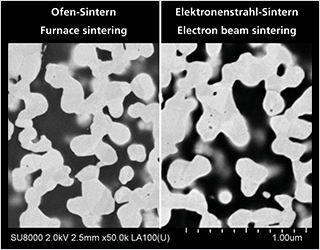

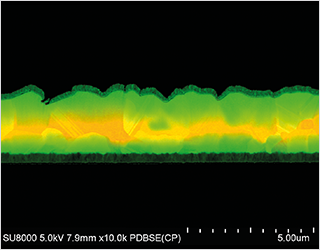

S. Saager, B. Scheffel, O. Zywitzki, T. Modes, M. Piwko, S. Doerfler, H. Althues, C. Metzner

Porous Silicon Thin Films as Anodes for Lithium Ion Batteries Deposited by Co-Evaporation of Silicon and Zinc

Surface and Coatings Technology

Vol. 358, 2019, p. 586 – 593

M. Top

Roll-to-roll deposition of silicon plasma polymers

Converting Quarterly

Vol. 9, Nr. 1, Quarter 1, 2019, p. 56 – 62

D. Wang, J. Hauptmann, C. May

OLED Manufacturing on Flexible Substrates Towards Roll-to-Roll

MRS Advances

Vol. 4, Issue 24, 2019, p. 1367 – 1375

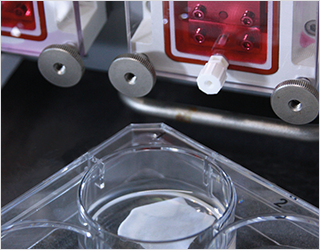

A. Thabet, R. Schmäschke, J. Fertey, B. Bangoura, J. Schönfelder, M. Lendner, S. Ulbert, A. Daugschies

Eimeria tenella oocysts attenuated by low energy electron irradiation (LEEI) induce protection against challenge infection in chickens

Veterinary parasitology

Vol. 266, 2019, S. 18 – 26

S. Barth, S. Derenko, H. Bartzsch, O. Zywitzki, T. Modes, F. Patrovsky, V. Fiehler, T. Uhlig, P. Frach, L. M. Eng

Influence of Growth Conditions and Film Thickness on the Anodization Behavior of Sputtered Aluminum Films and the Fabrication of Nanorod Arrays thereof

Thin Solid Films

Vol. 676, 2019, p. 1 – 7

S. Barth, H. Bartzsch, J. Hildisch

Piezoelectric and Electrically Insulating Coatings

GIT Laboratory Journal

Vol. 23, 2019, S. 29 – 30

C. May, A. Hausdorf

Full speed ahead for SmartEEs

OPE Journal

Vol. 27, 2019, p. 20

D. Glöß, U. Hartung, A. Drescher, P. Frach, H. Bartzsch

Freeform and Laser Optical Coatings by Inline Magnetron Sputtering

OSA Publishing, OSA Technical Digest

Optical Society of America, 2019, paper WB.2

Y. Li, M. Kovačič, J. Westphalen, S. Oswald, Z. Ma, C. Hänisch, P. Will, L. Jiang, M. Junghähnel, R. Scholz, S. Lenk, S. Reineke

Tailor-made nanostructures bridging chaos and order for highly efficient white organic light-emitting diodes

nature COMMUNICATIONS

Vol. 10, 2019, Artikel 2972

S. Saager, B. Scheffel, O. Zywitzki, T. Modes, M. Piwko, S. Doerfler, H. Althues, C. Metzner

Synthesis of Porous Thin Films as Silicon Anodes for Lithium Ion Batteries

SVC Bulletin

Summer 2019, p. 24 – 36

J. Hesse

OLED Modules for Textile Integration

Photonics Spectra

September 2019, Open Acess Artikel

M. Fahland, S. Garner, G. Pollack

Roll-to-Roll Sputter Deposition of Low Resistance Electrodes on Ultrathin Glass

Proceedings of 62nd SVC Annual Technical Conference 2019

Long Beach, USA, 27. April – 02. Mai 2019, p. 1 – 4

B. Zimmermann, G. Mattausch, C. Metzner

Rate and Composition Control for Plasma-assisted EB-PVD Processes by Optical Emission Spectroscopy

Proceedings of 62nd SVC Annual Technical Conference 2019

Long Beach, USA, 27. April – 02. Mai 2019, p. 1 – 6

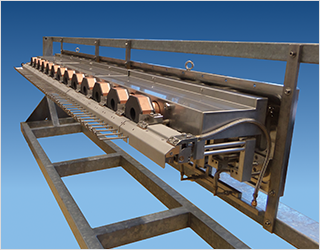

S. Saager, B. Scheffel, J.-P. Heinß

High-Rate Deposition of High-Pure Silicon Thin Films for PV-Absorber Layers by Crucible-free Electron Beam Physical Vapor Deposition

Proceedings of 62nd SVC Annual Technical Conference 2019

Long Beach, USA, 27. April – 02. Mai 2019, p. 1 – 10

J.-P. Heinß, F. Fietzke

EMC Shielding on Plastic Components by Electron Beam Evaporation

Proceedings of 62nd SVC Annual Technical Conference 2019

Long Beach, USA, 27. April – 02. Mai 2019, p. 1 – 10

P. Wartenberg, B. Richter, S. Brenner, M. Rolle, G. Bunk, S. Ulbricht, J. Baumgarten, C. Schmidt, M. Schober, U. Vogel

A New 0.64” 720p OLED Microdisplay for Application in Industrial See-Through AR HMD

SID Symposium Digest of Technical Paper

2019, p. 717 – 720

S. Barth, J. Hildisch, H. Bartzsch

Elektrisch isolierende und piezoelektrisch aktive Schichten

GIT Labor Fachzeitschrift

Vol. 7, 2019, S. 40 – 43

S.-C. Hermosa, M. Top, J. Dagar, J. Fahlteich, T. M. Brown

Quantifying Performance of Permeation Barrier-Encapsulation Systems for Flexible and Glass-Based Electronics and their Application to Perovskite Solar Cells

Advanced Electronic Materials

Vol. 5, Nr. 10, 2019, Artikel 1800978

R. Petrich, H. Bartsch, K. Tonisch, K. Jaekel, S. Barth, H. Bartzsch, D. Glöß, A. Delan, S. Krischok, S. Strehle, M. Hoffmann, J. Müller

Investigation of ScAlN for piezoelectric and ferroelectric applications

Onlineproceedings of IEEE

22nd European Microelectronics and Packaging Conference (EMPC) & Exhibition, Pisa, Italy, 16. – 19. September 2019, p. 1 – 5

H. Bartzsch, S. Barth, J. Hildisch, K. Täschner, R. Rückriem, M. Nestler

Sputter deposition of fluorine doped SiO2 films for temperature compensated SAW components

Onlineproceedings of IEEE

IUS Konferenz, Glasgow, Schottland, 06. – 09. Oktober 2019, p. 731 – 734

M. Kraus, Z. Diao, K. Weishaupt, J. P. Spatz, K. Täschner, H. Bartzsch, R. Schmittgens, R. Brunner

Combined ‘moth-eye’ structured and graded index-layer anti-reflecting coating for high index glasses

Optics Express

Vol. 27, Nr. 24/25, p. 34655 – 34664

E. Destouesse, M. Top, J. Lamminaho, H.-G. Rubahn, J. Fahlteich, M. Madsen

Slot-die processing and encapsulation of non-fullerene based ITO-free organic solar cells and modules

Flexible and Printed Electronics

Vol. 4, Nr. 4, 2019, Artikel 045004, 10 pages

R. Petrich, H. Bartsch, K. Tonisch, K. Jaekel, S. Barth, H. Bartzsch, D. Glöß, A. Delan, S. Krischok, S. Strehle, M. Hoffmann, J. Müller

Untersuchung von ScAlN für piezoelektrische und ferroelektrische Anwendungen

Proceedings MikroSystemTechnik Kongress 2019

28. – 30. Oktober Berlin, S. 412 – 416

S. Saager, B. Scheffel, J.-P. Heinß

High-Rate Deposition of High-Pure Silicon Thin Films for PV-Absorber Layers by Crucible-free Electron Beam Physical Vapor Deposition

Surface Coatings & Technology

Vol. 378, 2019, Artikel 125019

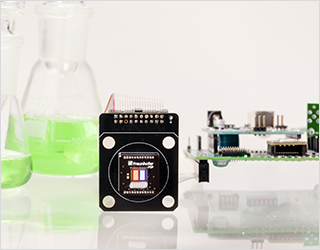

K. Fehse, D. Schlebusch, P. Wartenberg, S. Ulbricht, G. Bunk, S. Brenner, M. Schober, C. Schmidt, B. Richter, U. Vogel

OLED/OPD-on-Silicon for Near-to-Eye Microdisplays and Sensing Applications

Proceedings of The International Display Workshops

Vol. 26, 2019, p. 880 – 882

K. Fehse, D. Schlebusch, P. Wartenberg, S. Ulbricht, G. Bunk, S. Brenner, M. Schober, C. Schmidt, B. Richter, U. Vogel, S. Czihal, M. Morjan, M. Lau

Integration organischer Leuchtdioden auf einem Sensorchip zur Messung der Sauerstoffkonzentration in Gasen und Flüssigkeiten

Proceedings 14. Dresdner Sensor-Symposium

02. – 04. Dezember 2019, p. 49 – 51

B. Richter, P. Wartenberg, U. Vogel

Displays von ultra-low-power bis HD: OLED-Mikrodisplays für Augmented und Virtual Reality

elektronik industrie

Vol. 10, 2019, S. 54 – 56

Fraunhofer Institute for Electron Beam

Fraunhofer Institute for Electron Beam