Unique metal strip pilot plant with electron beam technologies for highly productive bipolar plate coating

Innovative technologies and applied research for the production, storage and processing of hydrogen for the energy transition

Hydrogen technology plays a crucial role in the energy transition and offers climate-friendly alternatives to fossil fuels. For the successful ramp-up of the hydrogen economy, highly productive technologies are needed for the cost-effective production of the required assemblies for generation and use. To this end, the in-line vacuum coating plant for sheets and metal strips for plasma-activated electron beam evaporation was qualified at Fraunhofer FEP for the highly productive and efficient coating of bipolar plates for electrolyzes and fuel cells. The results will be presented at the Clean Hydrogen Convention, October 25 – 26, 2023, at the Fraunhofer joint booth No. B-11 in hall 3, at the Dresden Trade Fair Center, Germany.

Hydrogen technology is seen as one key element for the success of the energy transition. Firstly, to store and transport renewable energy, and secondly to replace CO2 emissions from fossil fuels in industrial processes and in the transport sector with climate-friendly alternatives. As a result, many measures are currently being initiated in Germany as part of the German government's national hydrogen strategy.

The market ramp-up of the hydrogen economy requires highly productive technologies for the cost-effective series and mass production of assemblies for hydrogen production and use. Fraunhofer FEP is a leading developer of electron beam and plasma technologies for a wide range of applications. The advantages of electron beams can also be of great benefit in hydrogen technology, as they combine a wide range of physical, chemical and biological effects with high energetic efficiency, excellent precision and technological flexibility. One example is plasma-activated electron beam evaporation – a vacuum coating process that simultaneously enables high throughput and high coating quality. It is precisely this combination that is crucial for the coating of components, e. g. bipolar plates for electrolyzes as well as fuel cells.

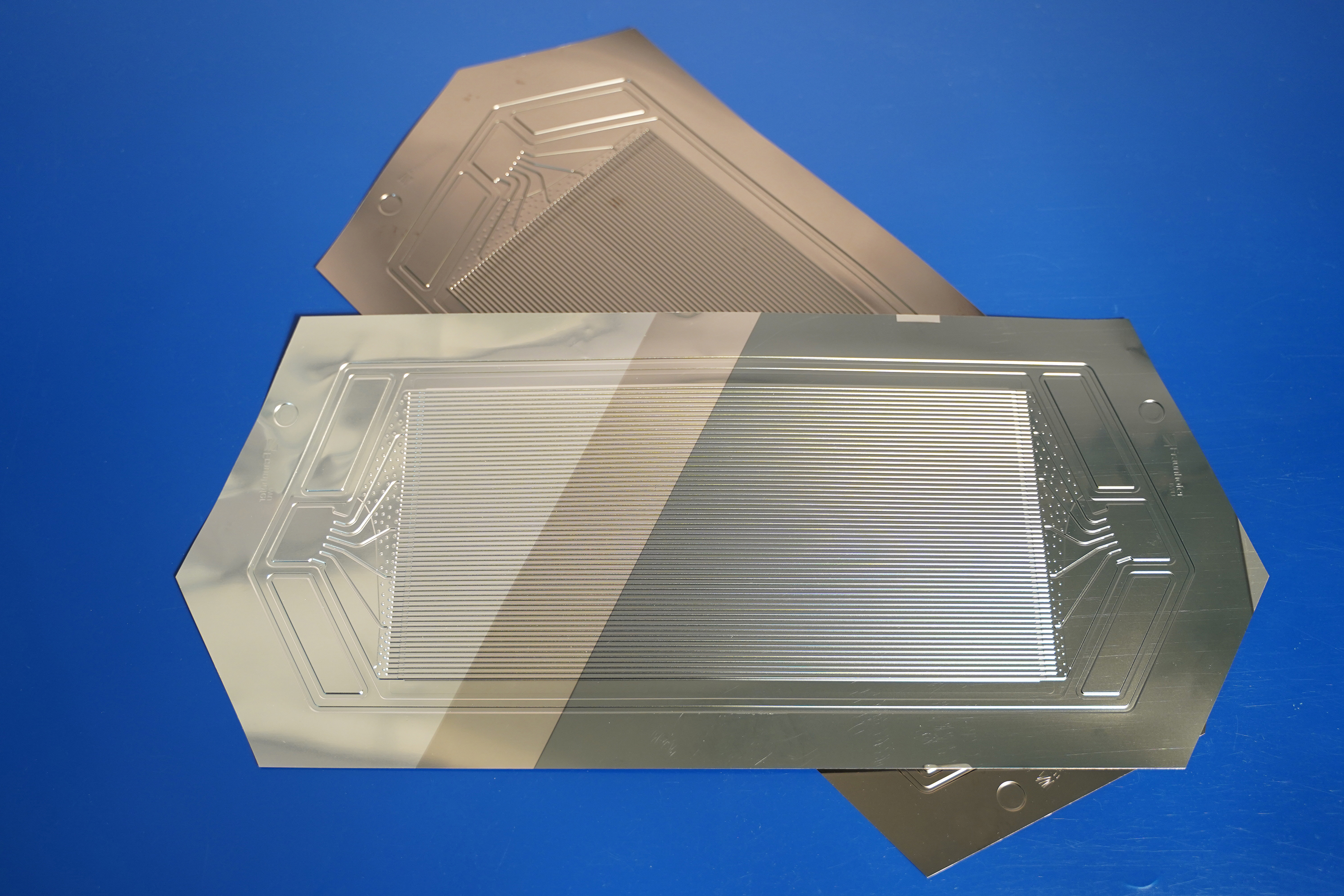

With the in-line vacuum coating system MAXI, Fraunhofer FEP has a unique pilot plant for the coating of metallic sheets and strips which has now been qualified for the coating of bipolar plates. Dr. Burkhard Zimmermann, division director for electron beam technologies at Fraunhofer FEP, explains: "Bipolar plates are an important element of fuel cells. They have to perform with long-term stability and have to withstand in a chemically aggressive environment. For this purpose, coatings are essential to reliably protect the bipolar plates and at the same time ensure sufficient electrical conductivity. With our equipment and know-how built up over decades in the development of highly efficient coating technologies, we can make a significant contribution to the high-rate coating of various substrates. Using plasma-activated electron beam physical vapor deposition, for example, ductile, formable coatings can be applied to metal strip before it is stamped into bipolar plates."

Coating the material prior to the embossing process is considered a decisive step for upscaling production in the roll-to-roll process. The challenge here is the formability of the coating. To ensure this, a dense macrostructure in the layer with crystallites as large as possible is required. These layer properties can be realized by the processes developed at Fraunhofer FEP, and with the plant MAXI, an innovative roll-to-roll as well as sheet-to-sheet line for the high-rate coating of corresponding substrates is available for research and development as well as for pilot production.

Initial results in the coating of 250 mm wide and 50 µm thick metallic strips with titanium already exhibited homogeneous layers in the thickness range of 200 nm with a coarsely crystalline structure, which could be produced at strip speeds of 10 m/min. Dr. Stefan Saager, head of the Coating Metal and Energy Technology group, explains: "The advantage of this process is that the substrate temperature can be limited to maximum values of less than 250°C. This means that the temperature can be kept to a minimum. Furthermore, due to the low heat load, sensitive materials such as electrically conductive polymers can be coated, which represent an innovative alternative for batteries and fuel cells."

The scientists will present the possibilities of high-rate coating for components in hydrogen technology as well as other focus topics in the use of electron beam and plasma technologies during the Clean Hydrogen Convention 2023, at the Fraunhofer joint booth No. B-11 in hall 3, at Dresden trade fair center, Germany, from October 25–26.

Fraunhofer at Clean Hydrogen Convention 2023

25 – 26 October 2023

Dresden trade fair center

Fraunhofer joint booth no. B-11 in hall 3

https://hzwo.eu/veranstaltungen/cleanhydrogenconvention2023

The following exhibits and topics await you at the booth:

Bipolar plates for electrolyzers and fuel cells.

Unique pilot line for metal strips MAXI with electron beam technologies for highly productive bipolar plate coating

Talk:

Thursday, 26. October 2023

1:00 pm, NOW-stage CHC Fair, hall 3

Highly productive electron beam and plasma technologies for hydrogen applications

Dr. Burkhard Zimmermann, Division Director Electron Beam, Fraunhofer FEP

Fraunhofer Institute for Electron Beam

Fraunhofer Institute for Electron Beam