Experimental plant for coating bulk goods via plasma-activated high-rate deposition

A business unit at Fraunhofer FEP develops technologies for coating of substrates having non-even geometry.

These coatings allow, for example, improvement of corrosion resistance, scratch resistance, or abrasion resistance of components. Decorative requirements and other specific functionalities can also be realized by selecting suitable coating materials.

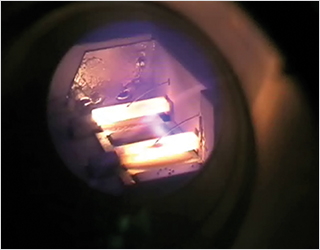

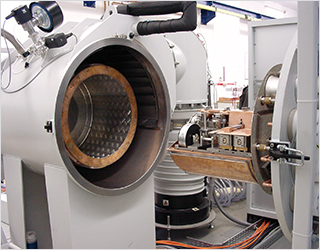

In our experimental plant ALMA 1000 we can process small components of any material as bulk goods. The technological setup allows plasma pre-cleaning (plasma-etching) of the small components, sputtering of adhesion promoting layers, and coating with various layer materials using plasma-activated high-rate deposition.

One main area of our work is optimization of the technological processes and the substrate handling for bulk product treatment, in order to adapt the functionality of the layer to the relevant coating requirements and to the substrate geometry.

The advantage of vacuum coating compared to conventional wet-chemical or metallurgical coating processes is the high layer quality and the range of layer structures that can be achieved. Environmental soundness and cost-efficiency are further positive side-effects of the technology.

| Coating chamber | Batch coater with bulk goods drum with unit for agitation of the bulk goods |

| Coating modules | 2 boat evaporators 1 hollow cathode 1 magnetron |

| Boat evaporators | max. 7 g/min per boat Continuous wire feed |

| Hollow cathode module | 300 A, 25 kW |

| Pulse magnetron power supply | 10 kW, 800 V, max. 30 A pulse current at up to 350 kHz pulse frequency |

| Etch/bias pulse power supply | 20 kW, 400 V, max. 200 A pulse current at up to 33 kHz pulse frequency |

| Bulk goods drum | max. 120 rpm Rotation direction can be reversed |

| Max. batch weight | 30 kg |

| Computer-controlled process management and data acquisition | |