In-line sputtering system for precision coating of large substrates – PreSensLine

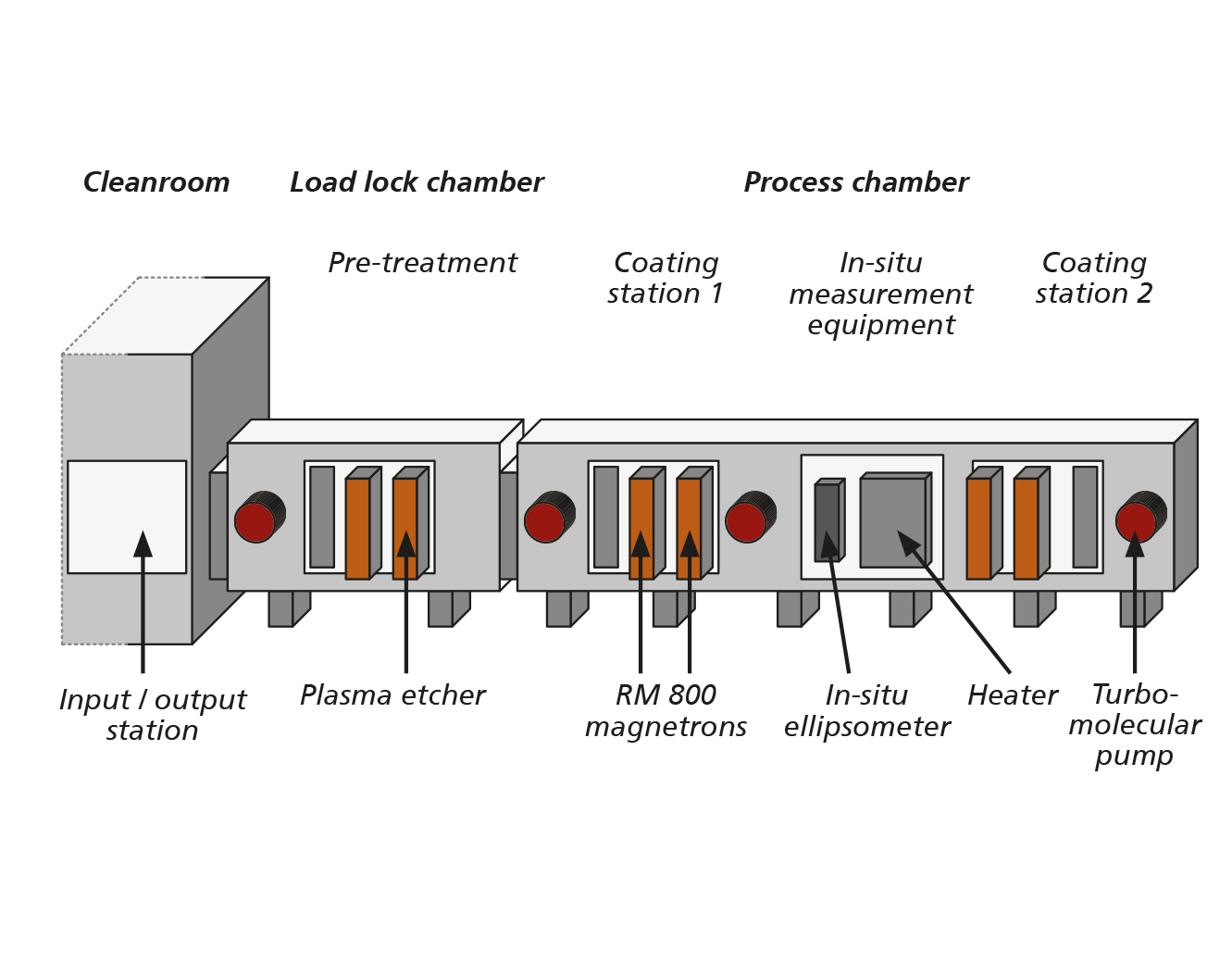

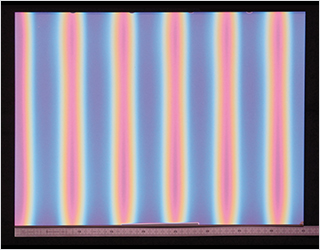

The PreSensLine is a coating system for dynamic coating by reactive pulse magnetron sputtering based on an in-line deposition principle. The equipment allows fabrication of high-precision complex multilayer coating systems, gradient coating systems and freeform coatings on large flat and curved substrates.

Prior to coating, the substrates are applied to the substrate carrier under ISO class-5 cleanroom conditions. Plasma etching for cleaning and magnetrons for the application of adhesion layers are available in the load lock chamber as pre-treatments.

Coating takes place in a process chamber comprising of two coating stations, each equipped with up to three sputter sources. A substrate heater as well as optical and pyrometric in situ measuring equipment is located between the stations.

Our expertise covers process optimization of reactive pulse magnetron sputtering for highly complex customer requirements. This includes to adjust a variety of layer properties to meet the demands from new applications in optics and sensor technology. This is possible by additional degrees of freedom (i. e. process parameters) based on innovative key components and technologies.

The coating system and sputtering sources employed are designed for precision coatings with low particle generation and characterized by high productivity.

The variety of available materials opens up almost unlimited opportunities for applications such as optical interference layer systems, electrical and piezoelectric layers, active sensor layers as well as protective and barrier layers.

Technical specifications

| Coating process | Reactive pulse magnetron sputtering (two coating stations each with two RM 800 magnetrons) |

| Substrate handling | Substrate handling within an ISO class-5 cleanroom |

| Substrate pre-treatment | Plasma etching (RP 800 Plasmatreater), adhesion layers |

| Combined substrate movement | Very precise substrate translation and rotation by linear and rotation motors, excellent accuracy +/- 0.025 % High dynamics: linear up to 0.5 m/s and 3 m/s², rotation up to 7200 °/s (1200 rpm) and 360 °/s² |

| Substrate dimensions | 650 mm × 750 mm × 120 mm, up to Ø 550 mm for rotating substrates |

| Optimized design for minimal particle generation |

|

| Base / process pressure | 1·10-6 mbar / 1·10-3 ... 1·10-2 mbar |

| Inert / reactive gases | Ar / O2, N2 |

| Vacuum pump-down system | Oil-free pre- and high-vacuum pumps |

| Process options | Substrate heating (up to 400°C), substrate bias (DC or pulse) |

| In situ measurement technology | Ellipsometer, pyrometer |

Technologies

- Coating deposited by means of reactive pulse magnetron sputtering with RM 800 magnetrons

- Power supplies with UBS-C2 unipolar /bipolar switching unit (incl. unipolar, bipolar and hybrid pulse modes)

- Reactive-gas process control by Spectrometer-Process Control Unit (S-PCU plus)

- Plasma etching for substrate pre-treatment

- Precise substrate movement (high-precision positioning accuracy and speed variation for substrate translational movement with superposed rotation)

- Freeform coatings on 3D substrate surfaces (e. g. on aspherical lenses) by position-dependent control of coating rates

Our offer

- Development and optimization of coating technologies and coating systems for demanding applications in optics and sensor technology

- Coating of samples and pilot production

- Development of key components such as magnetron sputter sources and plasma etchers

- Assistance in the cost analysis and technical implementation

- Transfer of technology and key components (for example of integrated packages) for production facilities

Fraunhofer Institute for Electron Beam

Fraunhofer Institute for Electron Beam