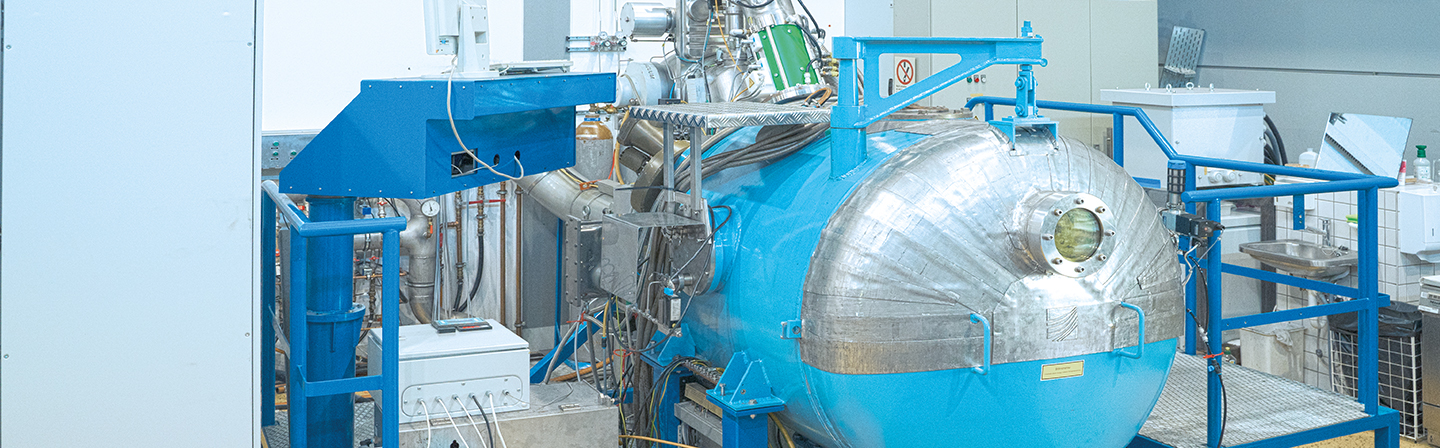

Laboratory coater with electron beam evaporator – EMO

Coating of Metal Sheets and Strips, Energy Technologies

We deal with large-area vacuum coating of metallic plates and strips with high deposition rates. In addition to the environmental friendliness of our process, another advantage is the almost inexhaustible range of layer materials that can be used which far exceeds the materials that can be applied for conventional surface modification.

Coating of Parts

We coat 3-dimensional objects made of metal, ceramics, or glass in order to adapt their surface properties and so improve their functionality and service life. Using vacuum coating technologies such as sputtering technology, plasma-activated high-rate deposition, and high-rate plasma-enhanced chemical vapor deposition (PECVD), we improve the resistance of tools and components to corrosion, scratching, and abrasion. Decorative features, demanding optical properties, biofunctionality, and biocompatibility can also be achieved by applying suitable layers and multilayer systems.

Technical specifications

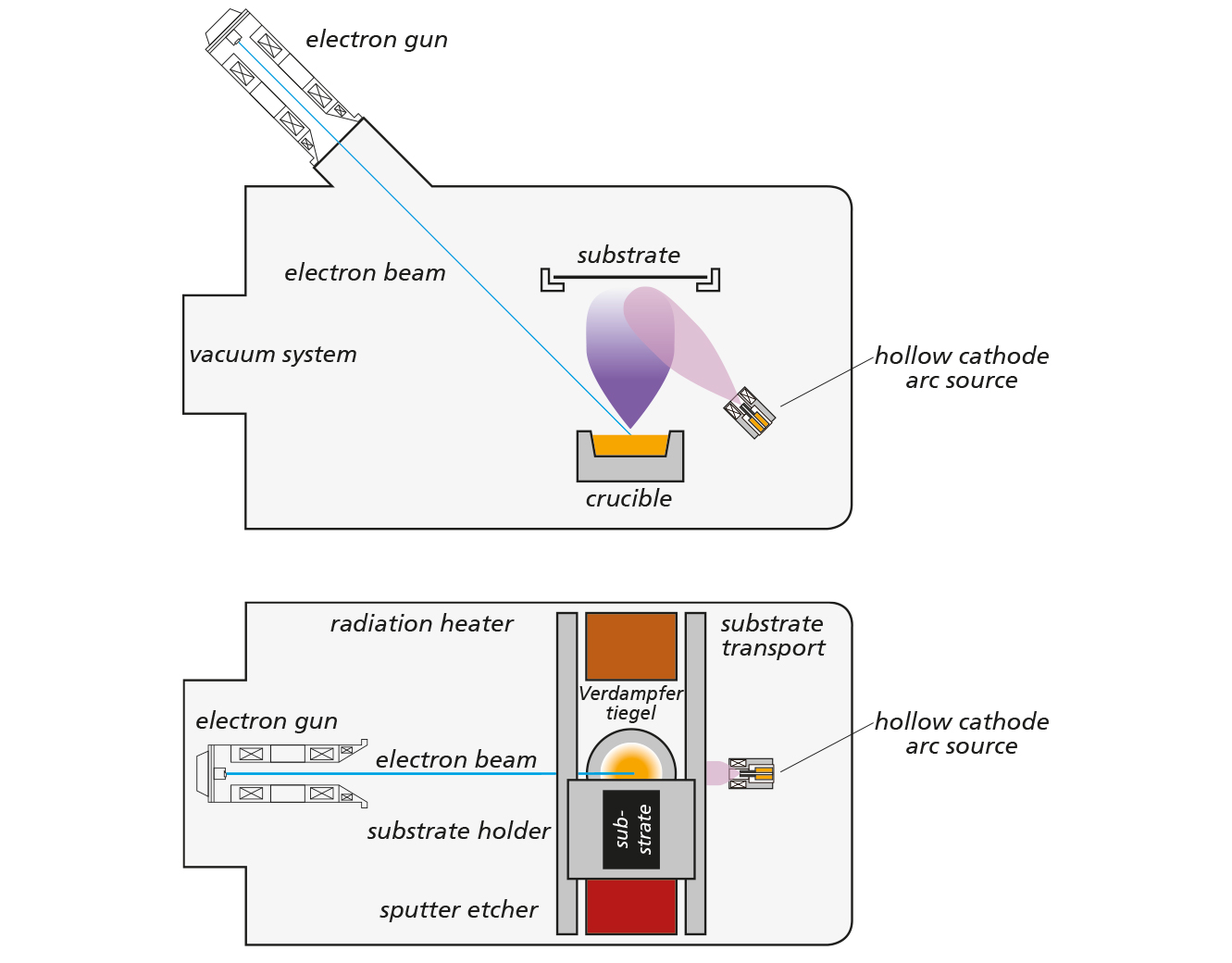

| Electron gun | 120 kW / 40 kV |

| Plasma activation | Hollow cathode arc sources (HAD process) Spotless arc activated deposition up to 1000 A (SAD process) |

| Crucibles | Water-cooled copper crucible Hot crucible (graphite, ceramics) |

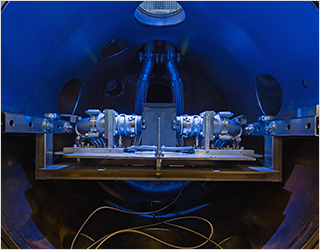

| Substrate size (sheets) | max. 100 mm × 200 mm |

| Substrate speed | up to 0.1 m/s |

| Additional equipment | Radiation heater: max. 4 kW Plasma etcher: max. 3 kW DC magnetron: max. 5 kW |

Fraunhofer Institute for Electron Beam

Fraunhofer Institute for Electron Beam