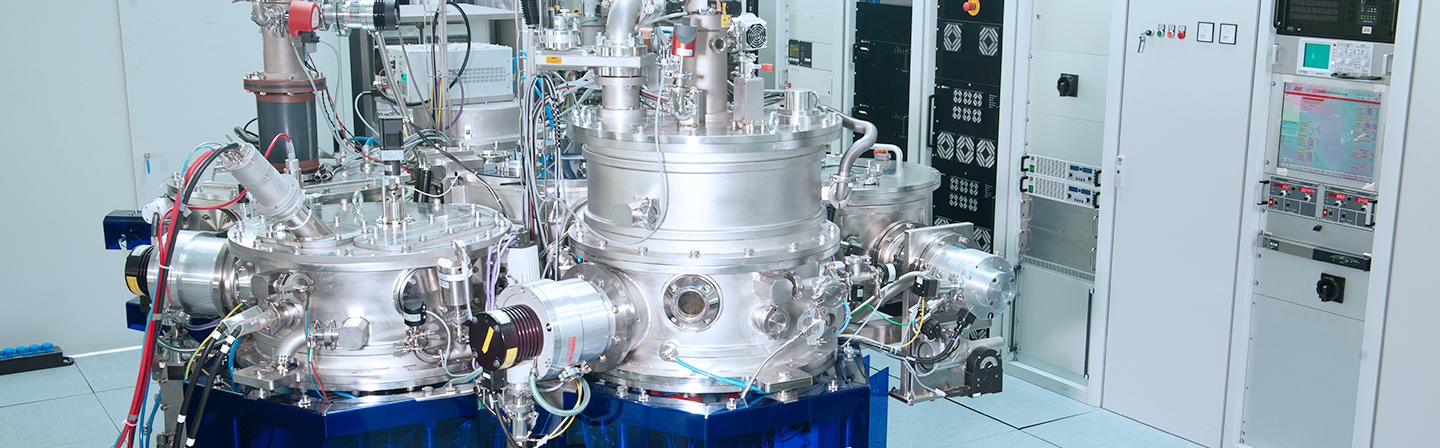

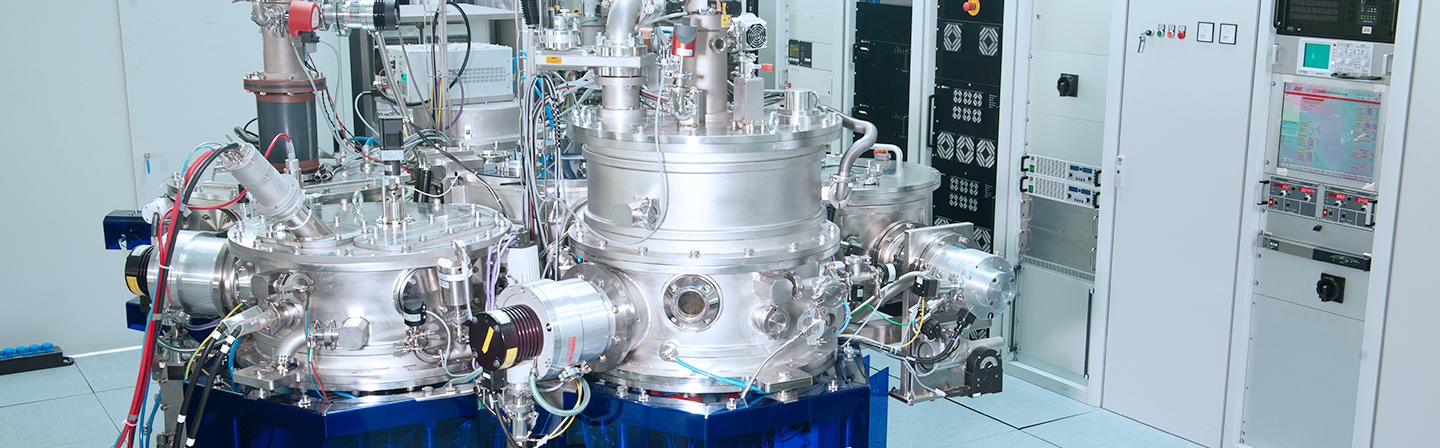

Vacuum cluster tool for complex coating and structuring processes

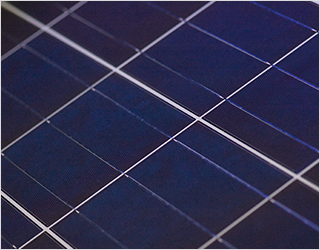

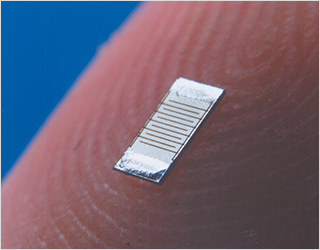

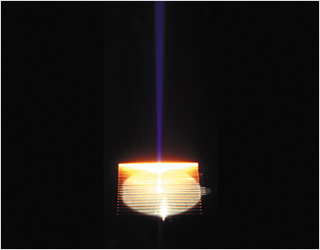

Complex vacuum process chains can be simulated within the closed ERICA system. This makes it possible to carry out cost-effective technological development and feasibility studies of coating and structuring steps in any desired sequence. The five interlinked chambers in ERICA are equipped for pre-treating substrates, for vacuum-coating, as well as for modifying and etching these surfaces. The ERICA internal conveyor system is designed for flat substrates (silicon wafers, sheet glass, film, etc.) up to a diameter of eight inches and maximum thickness of 3.5 mm. The versatility of this prototyping system makes it ideal for technological development of complex process chains such as solar cell manufacturing, abrasion-resistant and optical coatings, as well as for etching features and modifying surfaces, for example.