Flexible materials such as plastic webs, metal strips and foils, ultra-thin glass, textiles, and membranes find their application in many innovative products. The range of applications extends, for example, from packaging films to smart windows.

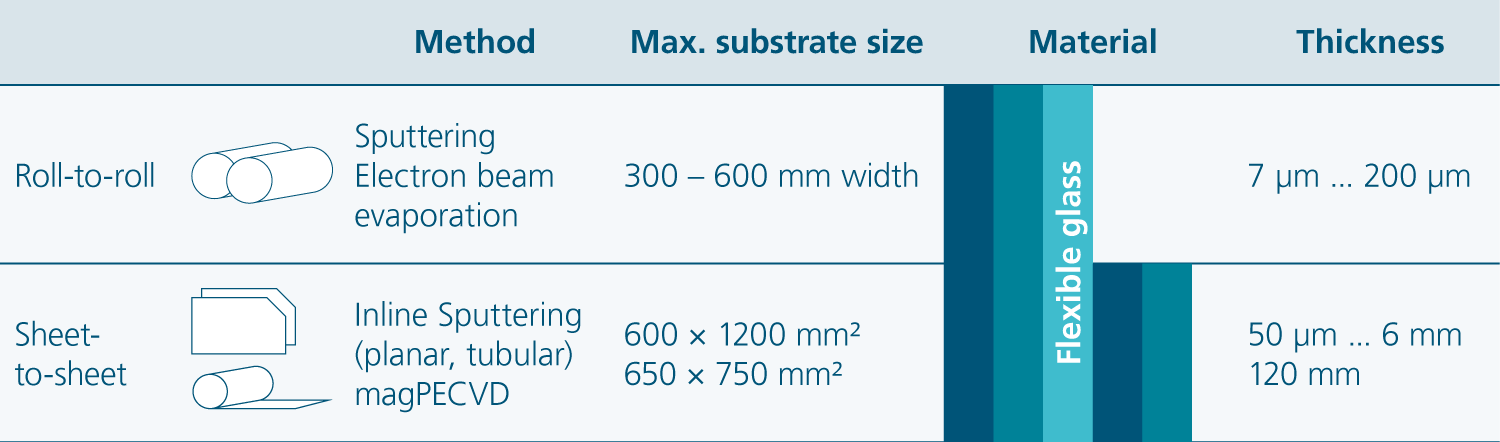

We develop and utilize roll-to-roll technologies to coat and modify flexible materials for various purposes. Our core competence includes a range of roll-to-roll coating technologies such as slot-die coating followed by electron beam curing, pulsed magnetron sputtering, electron beam evaporation, thermal evaporation, and PECVD. These coating technologies are complemented by processes for plasma and ion treatment of the surfaces of flexible materials. Process control methods ensure quality and reproducibility in the development and production process. The mentioned technologies are applied and further developed by us in a project-specific manner. We handle development projects for our customers from feasibility studies to industrial implementation. For this purpose, we have unique roll-to-roll systems available, ranging from laboratory to pilot scale.

Roll-to-roll Technology for Coating and Functionalizing Flexible Materials

- Coating and modifying flexible materials such as plastic web, metal strips and foils, ultra-thin glass, textiles, membranes

- Industrially applicable roll-to-roll technologies for innovative applications of flexible materials

- Roll-to-roll coating technologies such as slot-die coating followed by electron beam curing, pulsed magnetron sputtering, electron beam evaporation, thermal evaporation, and PECVD

- Unique roll-to-roll pilot systems from laboratory to pilot scale

- Development projects for our customers from feasibility studies to industrial implementation

Fraunhofer Institute for Electron Beam

Fraunhofer Institute for Electron Beam