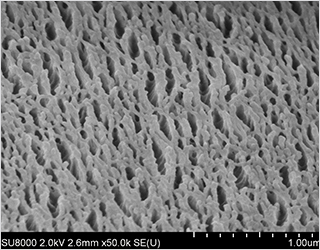

The Fraunhofer FEP has developed innovative processes for the efficient antireflection coating of films. The use of a proven plasma etching process, which has already been tested in the production of small and compact optical parts, now enables continuous processing in a roll-to-roll process.

Applications

Polymer films are of great importance in the packaging industry, especially in the food sector. Their applications range from packaging and protective packaging for pharmaceuticals and electronics to decorative elements and complex functions in displays or solar cells. With the increase in mobile electronic devices, these applications in particular are gaining in importance.

Anti-reflective properties

Numerous applications require the optical properties of films to be adapted, with anti-reflective coatings being particularly important. Transparent films, such as PET, reflect about 12% of light, which is higher than glass. Polymer films with anti-reflective properties are ideal for large surfaces, such as glazing in display cases, optical elements in projection devices and vehicle parts. Anti-fog and anti-reflective surfaces are also of great interest for sports glasses, windscreens and displays.

Cost efficiency

The cost-effective availability of anti-reflective films is crucial for commercial use, especially for medium-sized companies. The developed plasma etching offers a process that ensures low production costs with high quality. The focus on implementation on a roll-to-roll coating line enables excellent material logistics and flexibility for different roll materials. The continuous process sequence also ensures a further reduction in production costs.

Discover the advantages of our plasma etching processes for your applications and benefit from innovative solutions for anti-reflective polymer films!

Fraunhofer Institute for Electron Beam

Fraunhofer Institute for Electron Beam