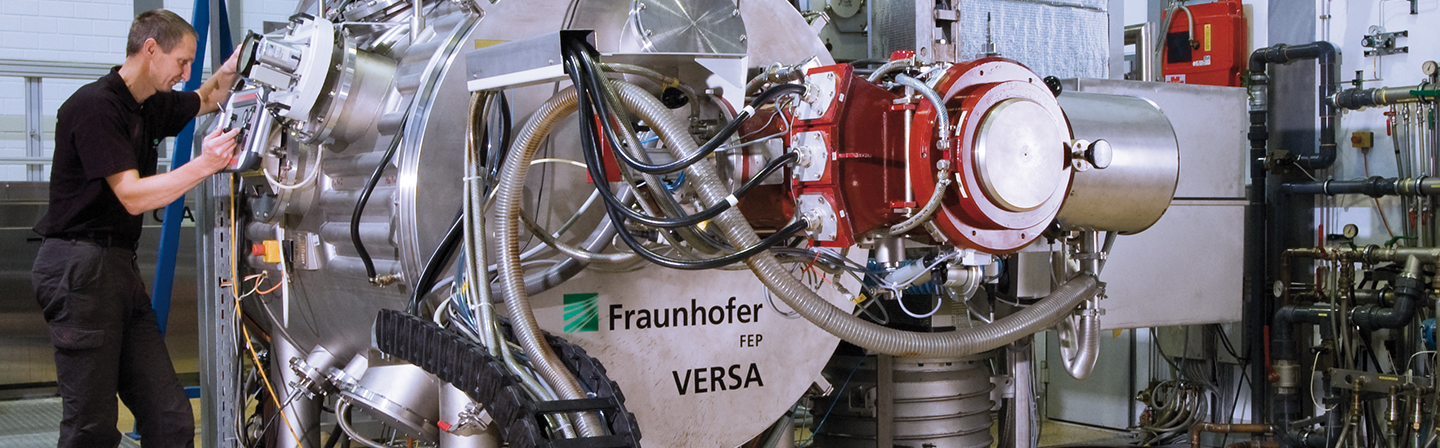

Pilot plant for plasma-activated electron beam vapor deposition

High-rate electron beam physical vapor deposition (EB-PVD):

| Electron beam gun | up to 300 kW / 45 kV |

| Substrate dimensions | up to 120 mm × 200 mm (metal, glass, wafers, etc.) |

| Substrate speed | 1 cm/s ... 1 m/s |

| Substrate pre-treatment | Handling under inert gas environment possible by using a glovebox Radiative heater max. 6 kW Sputter etcher max. 6 kW DC magnetron max. 8 kW |

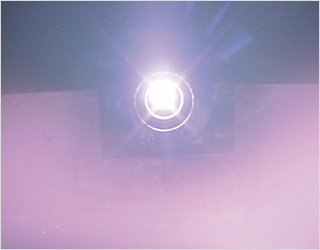

| Plasma activation | Spotless arc-activated deposition process (SAD process) Hollow cathode arc-activated deposition process (HAD process) 2000 A – arc power supply |

| Evaporation crucibles | Water-cooled copper crucibles Hot ceramic crucibles |

| In-situ measurement systems | Coating rates Optical emission measurements Substrate temperature Evaporation rates Power balance |