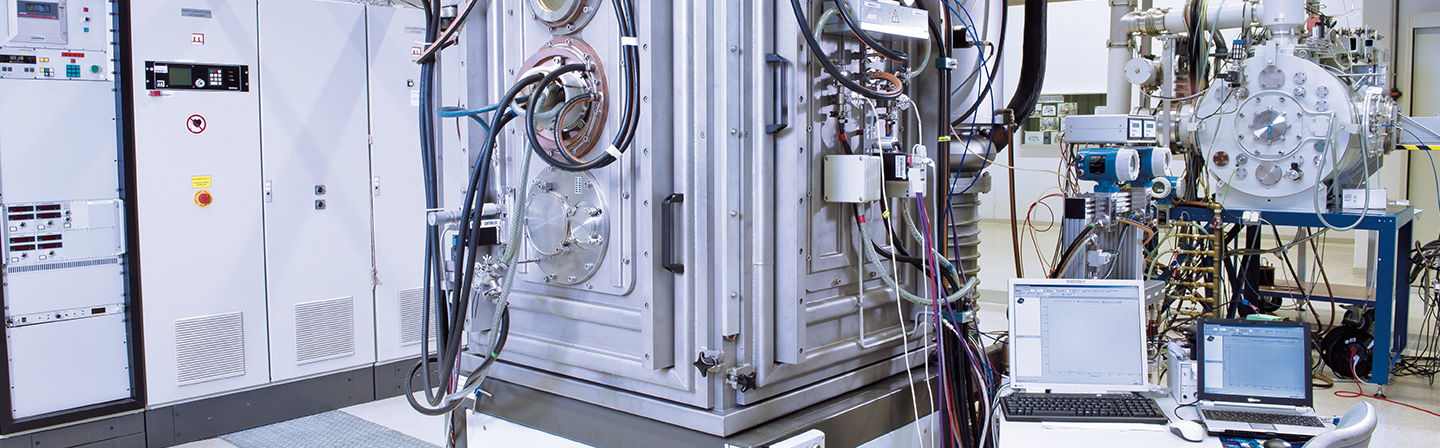

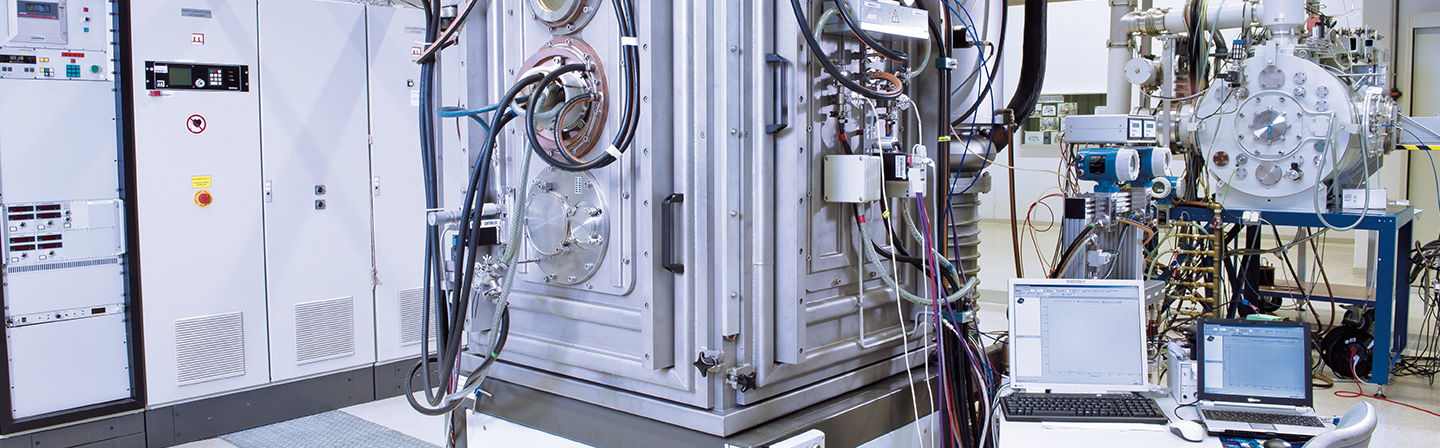

Pilot plant for the coating of components

Combined processes of plasma-activated high-rate evaporation, magnetron sputtering and PECVD

Combined processes of plasma-activated high-rate evaporation, magnetron sputtering and PECVD

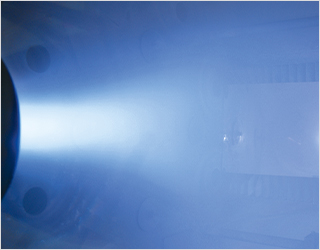

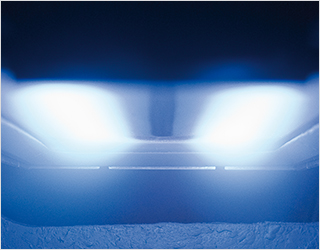

One area of work at Fraunhofer FEP is the development of technologies for vacuum coating of components that are characterized by non-planar shapes. Fraunhofer FEP applies its expertise in electron beam technology to the field of component coating. In our pilot plant NOVELLA we have implemented the necessary technological facilities: an electron-beam source that enables coating at very high deposition rates, two hollow-cathode plasma sources for plasma generation and vapor activation, and optional a sputter magnetron.

A versatile component transport system provides variable sequences of motion, such as those for depositing multiple layers on 3-dimensional substrates. With this equipment, component coating gains access to productive processes beyond the industrially established techniques like arc evaporation and magnetron sputtering.

The device can be used for physical vapor deposition (PVD) as well as plasma-enhanced chemical vapor deposition (PECVD) and combined processes. We have thus a powerful tool to develop optimized coatings that can meet increasingly demanding requirements. Among these are specific properties for wear and corrosion protection, electrical conductivity, magnetic shielding, and decorative effects of components.

An effective plasma-based pre-treatment is an essential step in all coating processes. Furthermore, plasma activation enables the structure of the deposited layers to be influenced in a controlled manner. This makes the deposition of dense, compact layers feasible even at coating rates of up to several microns per minute. The prototype NOVELLA system enables us to demonstrate extremely productive short-cycle processes at very high coating rates as a preliminary step for implementation of these processes in industrial production lines.

| Substrate | Diameter up to 150 mm Length up to 300 mm Weight up to 15 kg |

| Substrate movement | Rotation up to 100 U / min Translation up to 10 m / min |

| Two-chamber unit | Load-lock chamber including substrate pre-treatment Coating chamber |

| Pre-treatment | Sputter-etching Heating (up to 600°C) |

| Hollow cathode plasma source | Power supply 30 kW, 200 A Plasma density: 1018 / m3 Argon-ion-current density: 40 mA / cm2 |

| Sputter source | Planar double magnetron Power supply max. 60 kW, pulse rate max. 50 kHz |

| Electron beam source | Plasma-based gun 120 kW / 40 kV |

| Evaporation crucible | Water-cooled copper crucible Hot ceramic crucible Special forms (rotatable crucible, crucible with rod feeding, multiple material evaporation) |