Roll-to-roll inspection system

For thin film applications a roll-to-roll optical inspection system is needed which fulfills the defect resolution requirement down to 1 µm region.

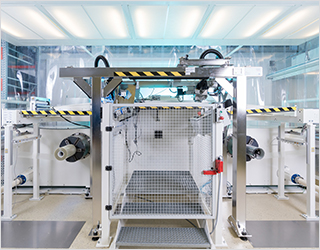

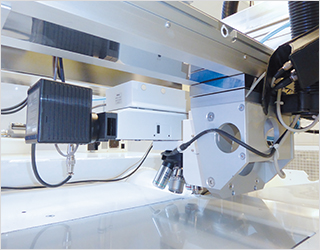

Fraunhofer FEP has developed a winding / rewinding system with integrated optical inspection system installed in an ISO class 6 clean area.

The system can operate with the following inspection modes:

- 100% web inspection with CCD linescan cameras with a pixel resolution down to 14 µm

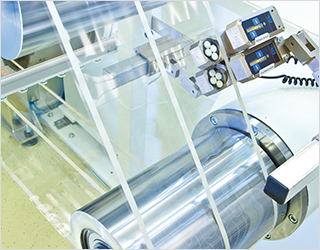

- Automatic image recording with xy moveable microscope with high resolution down to 1 µm, depending on the objective magnification

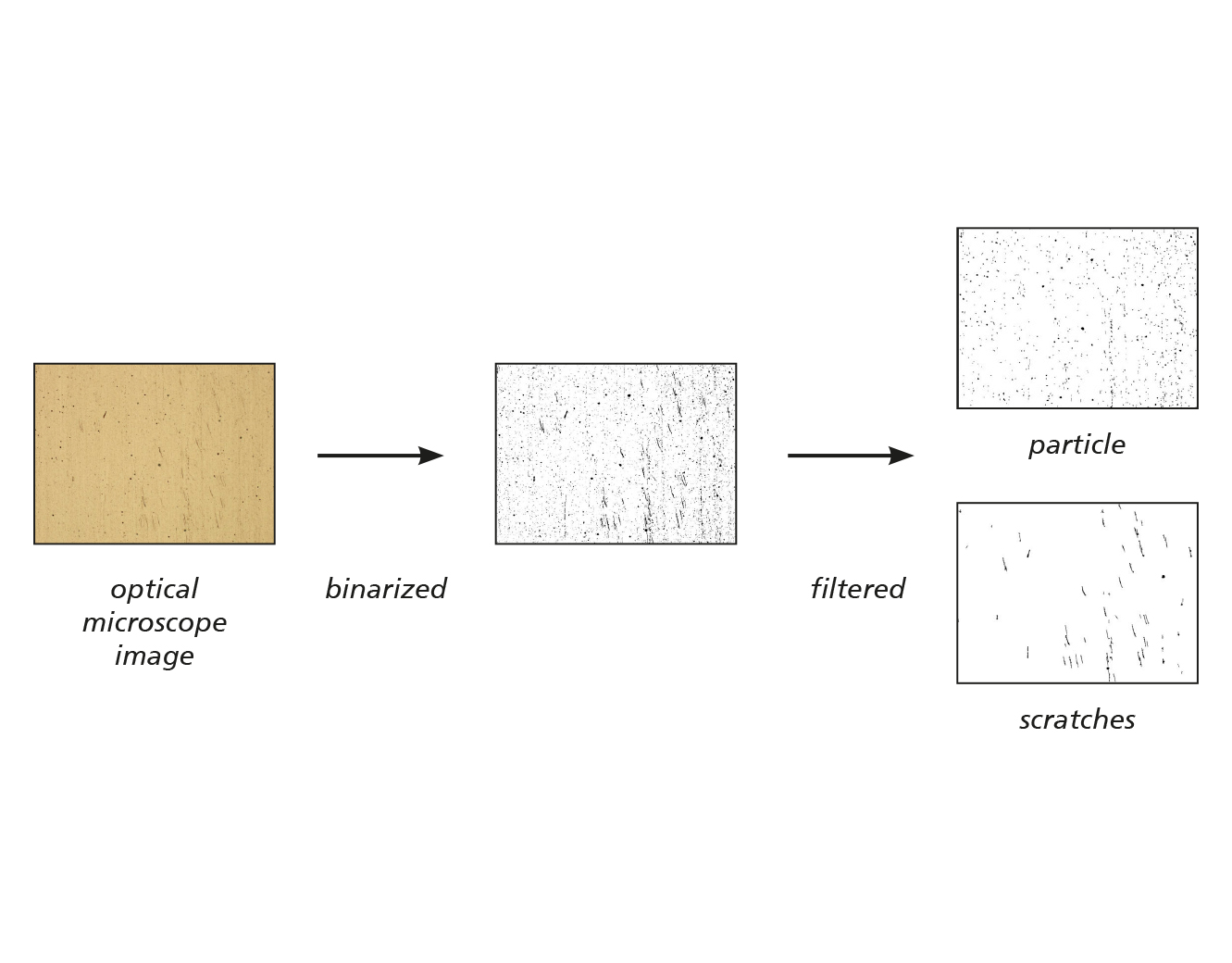

High resolution analysis of surfaces

The roll-to-roll inspection system consisting of CCD-linescan cameras is a powerful instrument to detect defects on homogeneous webs. The system can automatically detect both light (light-scattering) and dark (light-absorbing) defects that contrast with or differ in topography from the surface of the product. A rollmap is generated from this, which shows the positions of the errors along and across the web. The defects will be classified by their brightness and shape.

A more detailed defect analysis of the 100% web inspection is possible by checking the detected defects, by moving the microscope to the area of interest. The higher resolution allows a better understanding of the defect origin.

The web handling avoids any front side contact to maintain the surface quality during the inspection. The winding unit is suitable for metal, glass and plastic films with a width of up to 320 mm and a thickness between 25 µm and 500 µm.

To protect the surface of the track, it is possible to wrap Interleaf Liner both from above and below. Web edge sensors ensure that the strip is winded straight. If necessary, a contact cleaning system can also be used to clean the web.

Position data defects from pre-inspection can be compared with the position data of a post-inspection. There is a possibility to represent additional, removed and remained defects of a process in one chart.

This method is suitable for:

- Identification of rollers / machines which cause scratches

- Comparison of cleaning technologies

- Determination of particle contamination by processes

Technical specifications

| 100% web inspection by CCD linescan cameras | Automatic image recording with moveable microscope | |

| Application | Unstructured webs Optical scanning of the surface during winding process |

Unstructured and structured sheets of different sizes, foils and webs |

| Resolution | Pixel resolution 14 µm Defect resolution 40 – 50 µm (depends on the material) |

High resolution depending on magnification of used objective down to 1 µm region |

| Defect classification | Possible | Limited possible |

| Modes | Transmitted and reflected light mode | Different reflecting light modes (bright field, dark field, DIC, UV) |

Our offer

- Roughness measurement by atomic force microscopy

- 100% web inspection

- Defect density determination down to defect sizes ≈ 1 µm

- Quantitative defect classification

- Separate defect density determination of individual defect types

- Thermal infrared measurement

- Luminescence-current-voltage (LIV) measurement

- White light interferometry

Fraunhofer Institute for Electron Beam

Fraunhofer Institute for Electron Beam