ILA 900

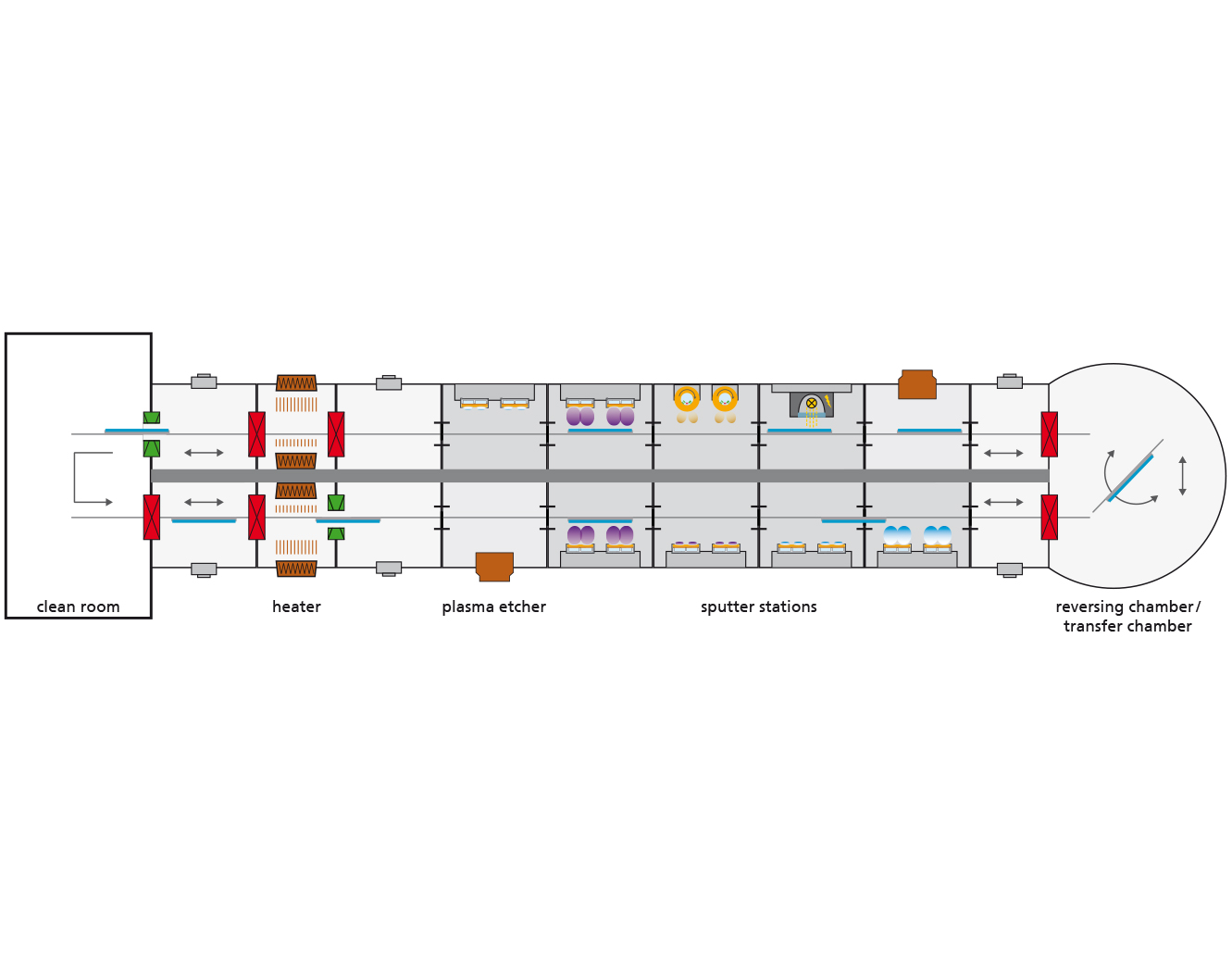

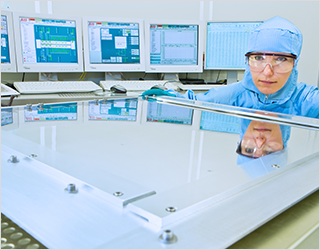

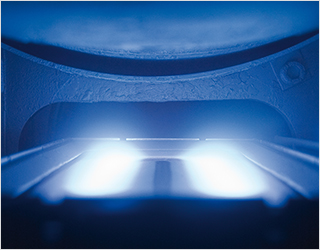

Layers and layer systems are applied to flat substrates at the Fraunhofer FEP using sputtering technologies. The special expertise of the Fraunhofer FEP in this field is pulse magnetron sputtering (PMS) and the control of reactive sputter processes. First of all suitable layer systems are identified for specific applications and then the sputter processes are adapted and optimized to the requirements of the relevant tasks. The objective is to deposit layers of high quality at favorable cost. The Fraunhofer FEP has special expertise here in the development of technological key components for PMS and process control. The ILA 900 in-line sputtering plant allows layers and layer systems to be applied to flat substrates of size up to 1200 × 600 × 60 millimeters. The plant is designed in a way that up to eight processing stations can be used to deposit metals and metal oxides / nitrides / oxynitrides reactively or from ceramic targets via unipolar or bipolar magnetron sputtering. This can be carried out on either one side or both sides.

Example applications of the layers and layer systems are architectural glass (low-E coatings / solar control coatings), transparent conducting electrodes (TCO), and electromagnetic shielding (EMI) and antireflection (AR) coatings and antireflection-antistatic (ARAS) coatings in displays in electronic and photovoltaic devices.

Technologies

- Clean room conditions for substrate treatment

- Coating on one or two sides

- Substrate pre-treatment:

- RF sputtering

- substrate heating up to 500°C (radiation heater)

- industrial cleaning (washing and drying plant, disinfector)

- DC or pulsed magnetron sputtering:

- DC sputtering up to 60 kW

- pulse sputtering (sine) up to 100 kW

- pulse sputtering (square) up to 60 kW

- Non-reactive and actively stabilized reactive sputtering processes

- Single or dual magnetron sputter system (DMS system), planar or cylindrical targets

- Layer thickness homogeneity over 600 mm coating width: ± 1.5% (material-dependent)

- In-situ monitoring:

- layer resistance via contactless measurement

- optical transmission of the substrate

- substrate temperature via contactless measuring points (pyrometer)

- optical plasma emission for process control

- partial pressure: Mass spectrometer, lambda sensor for oxygen

- real-time measurement of the substrate temperature (and the carrier) via a thermocouple (radio data transfer)

- in-line temperature stabilization of the substrate (up to 250°C)

Technical specifications

| Multi-chamber in-line plant with: |

|

| Base pressure: | 2 × 10-6 mbar |

| Working pressure: | 10-4 … 10-2 mbar |

| Process gas inlet: | H2, O2, N2 |

| Standard substrate size: | 1.200 mm × 600 mm × 60 mm (larger dimensions on request) |

| Substrate speed: | 0.1 … 6 m/min |

| Target-substrate distance: | 80 … 150 mm |

Our offer

- Feasibility studies on new layer systems for specific applications

- Development of sputtering processes for functional layer systems and single layers under near-real production conditions

- Small series production for market introduction of new products

- Adaptation and supply of key components (for example power supplies, pulse and control units, also as integrated packages) for example for modernizing or expanding existing production plants

Fraunhofer Institute for Electron Beam

Fraunhofer Institute for Electron Beam