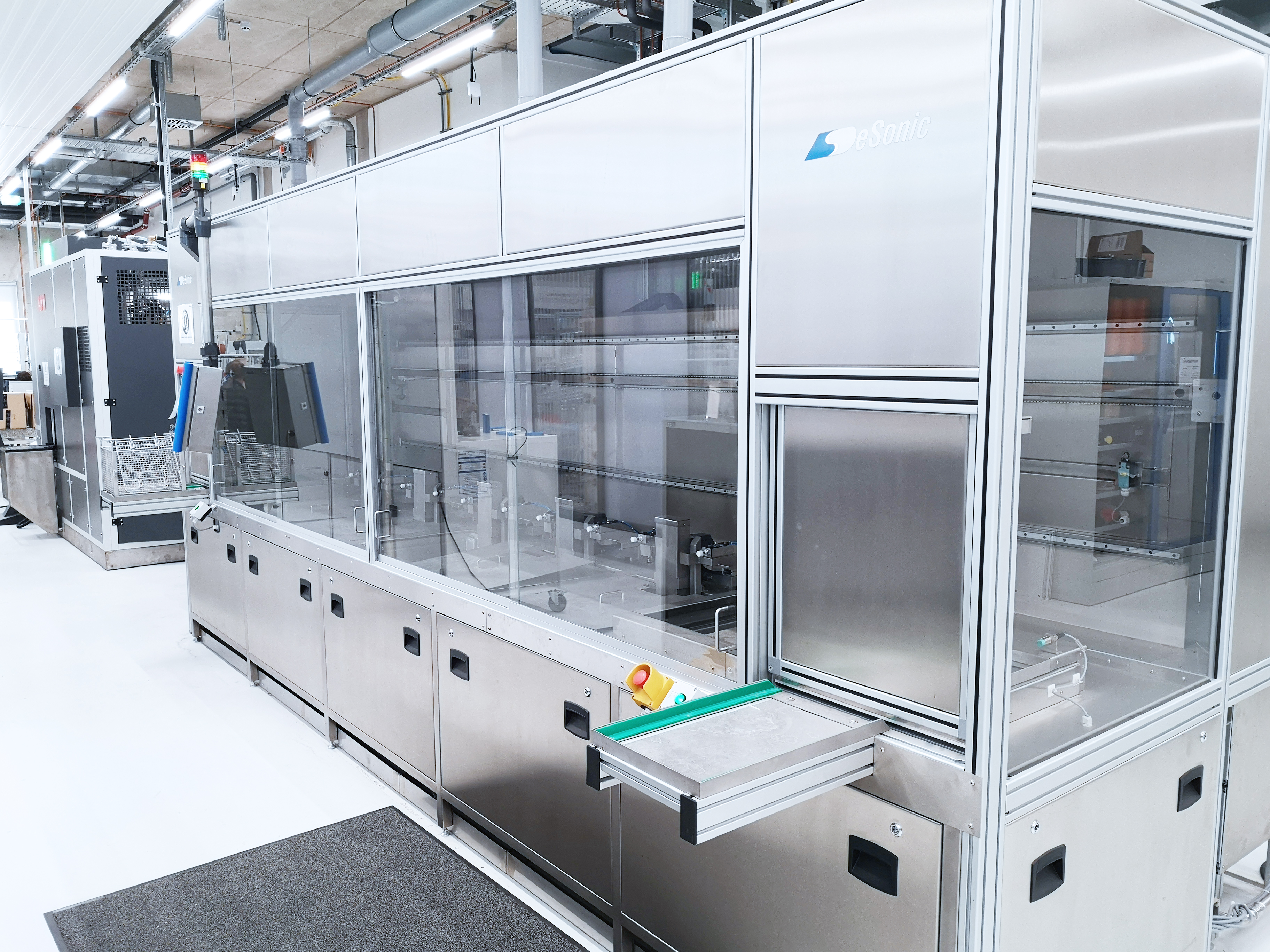

The cleaning equipment technology at Fraunhofer FEP offers innovative and reliable solutions for the thorough and precise pretreatment of surfaces. Using state-of-the-art cleaning processes, such as wet chemical cleaning, plasma cleaning, and special dry cleaning processes, substrates are optimally prepared for subsequent coating processes.

Our equipemt is designed for the efficient removal of particles, organic residues, and other contaminants, ensuring high surface cleanliness and maximum adhesion of coatings. Thanks to individually adjustable process parameters, different substrate materials and sizes can be treated, enabling a flexible and customized cleaning solution. Continuous process monitoring and optimization contribute to high quality and reproducibility of the cleaning processes.

Fraunhofer Institute for Electron Beam

Fraunhofer Institute for Electron Beam