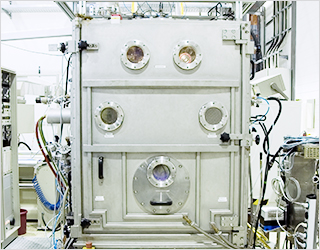

Roll-to-roll laboratory coating system – labFlex

The surface finishing of plastic films and other flexible substrates with thin layers enables these materials to be used in a wide range of applications. Coatings can be deposited cost-effectively and efficiently using vacuum-based roll-to-roll systems.

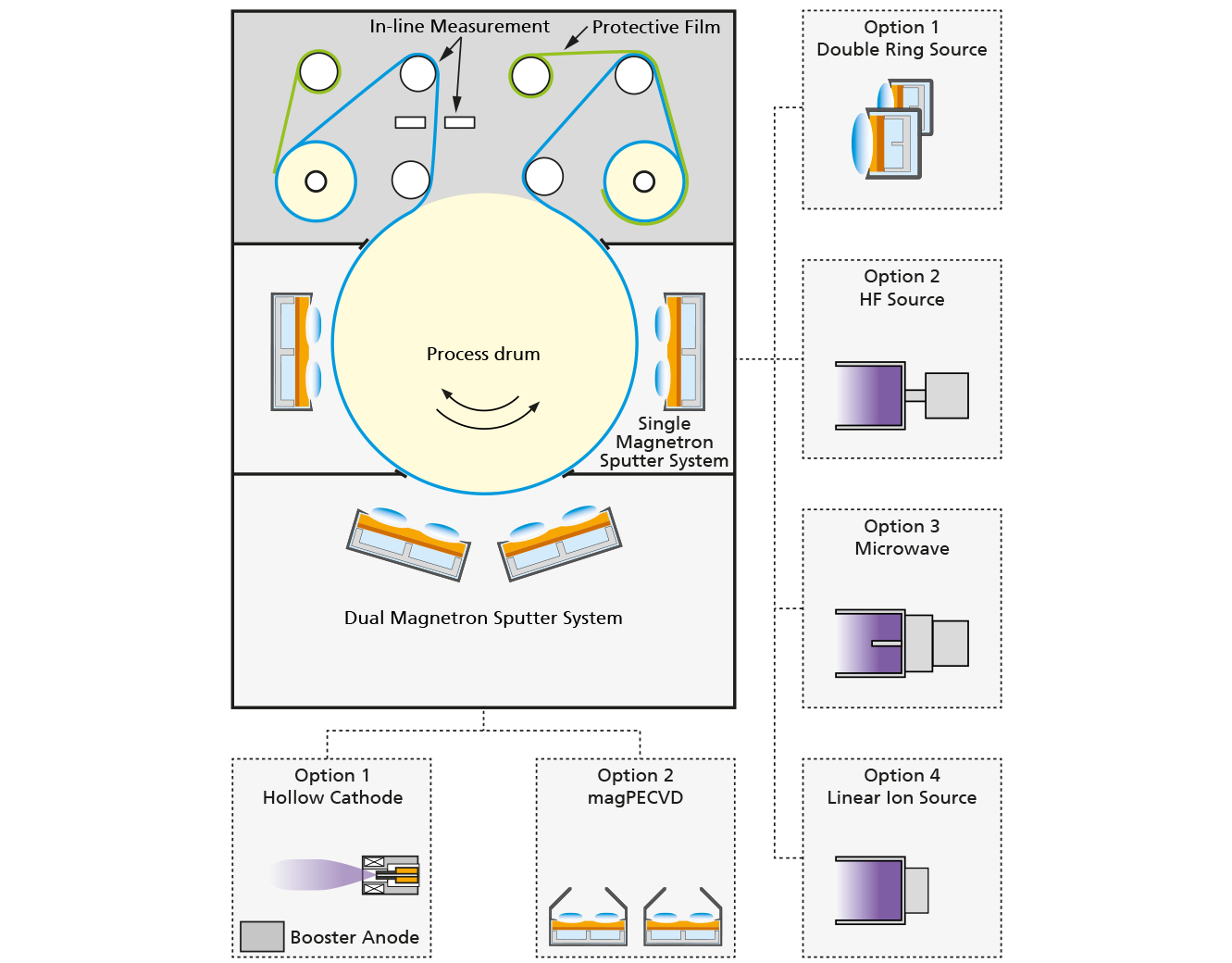

In the labFlex® 200 vacuum test system, optical, electrical and / or decorative functional coatings can be applied using sputtering processes and magnetron- or hollow cathode-supported PECVD processes.

The test system also offers the option of integrating other plasma sources, such as HF or microwaves and to test their suitability for the desired process.

There is a wide range of applications for the coatings that can be applied in the system:

- Optical coating systems for UV mirrors or as infrared-reflecting thermal barrier coatings

- Electromagnetic decoupling layers (EMC layers) or transparent conductive layers (TCOs) for displays

- Front and rear contacts, permeation barriers and/or TCOs for flexible (organic) solar cells

Thanks to the various options for installing plasma sources in the labFlex® 200 and its size, the test system is very well suited for initial feasibility studies of new or rare materials in the roll-to-roll process. It has optical and electrical in-situ measuring units. Thanks to its versatility, the Fraunhofer FEP has a complete technology for the development of multilayer systems under near-production conditions.

Technical specifications

| Substrate types (roll material) | Polymers, metals, membranes, textiles, paper |

| Substrate width | 100 ... 300 mm |

| Substrate thickness | 6 ... 250 μm |

| Substrate temperature control | -20 ... +60 °C |

| Layer materials | Metals, oxides, nitrides, plasma polymers |

| Coating stations | 3 |

| In-situ measurements | Optical transmission, electrical resistance |

| Special know-how | Protective film handling, Processing without touching the good side of the substrate |

Technologies

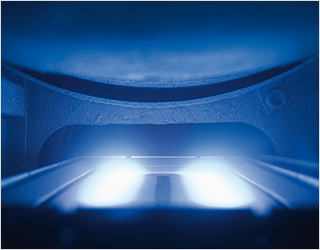

- Pulse magnetron sputtering:

- dual magnetron sputtering

- unipolar magnetron sputtering

- DC sputtering

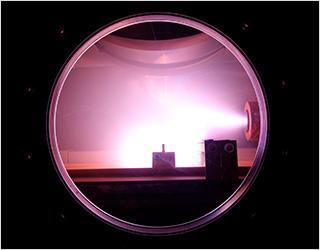

- PECVD

- hollow cathode enhanced

- magnetron enhanced

- Pre- / post-treatment

- linear ion source

- HF-/ microwave plasma source

- O2 plasma

Our offer

- Development of technologies for coating plastic films and other flexible materials

- Development of plasma pre-treatment processes

- Development of coating systems

(optical, electrical and decorative functional layers, barrier layers) - Development and testing of key components

- Sampling for tests and market development

- Investigations into the economic efficiency of coating processes

Fraunhofer Institute for Electron Beam

Fraunhofer Institute for Electron Beam