Roll-to-roll pilot sputter roll coater – coFlex

The surface refinement of polymer films and other flexible substrates by applying thin coatings allows these materials to be used in a wide range of products. Vacuum based roll-to-roll plants allow coatings to be efficiently applied at favorable cost.

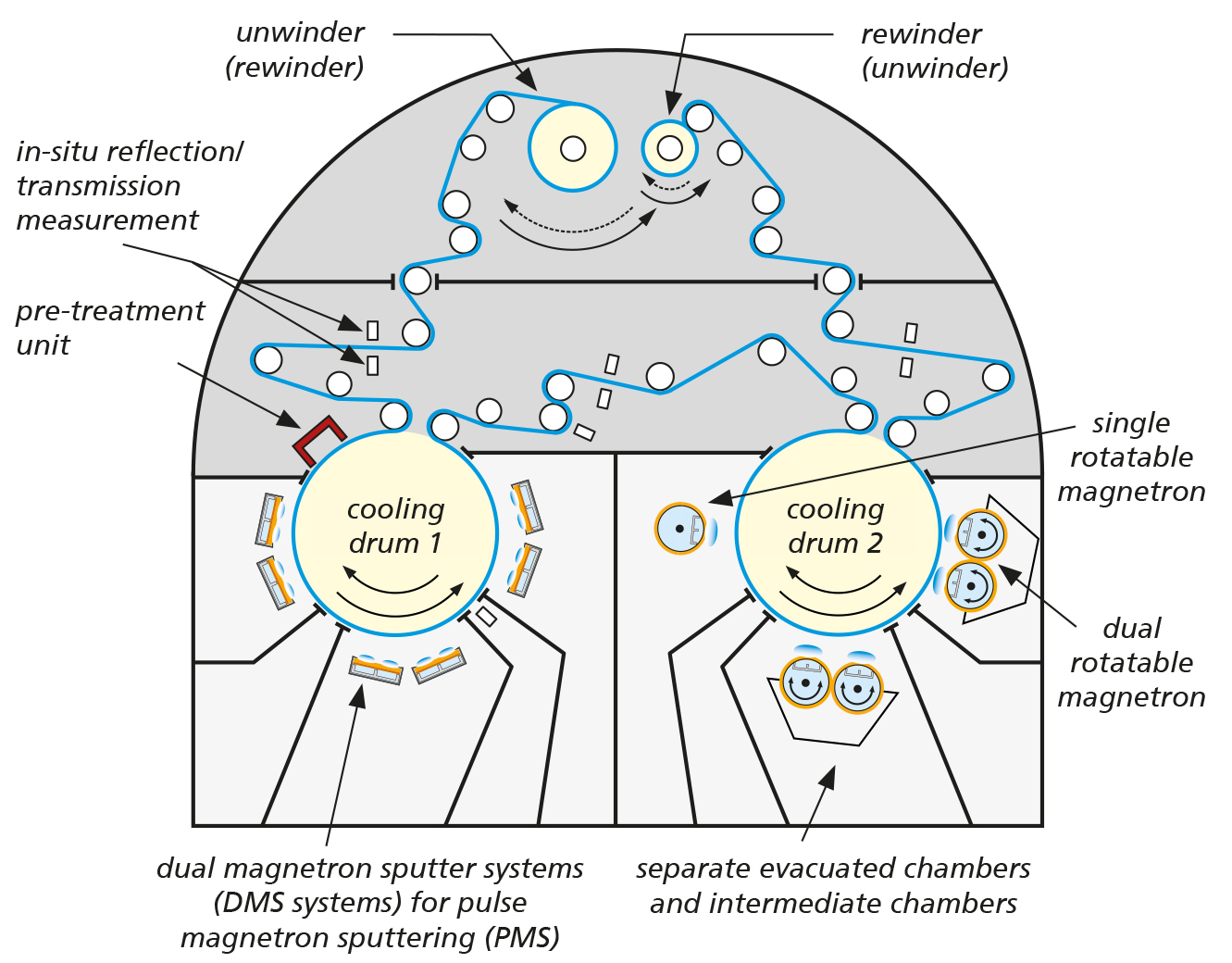

The coFlex® 600 vacuum web coating plant can be used to deposit optical, electrical, and decorative layers on substrates via sputtering techniques and magnetron PECVD processes. Line speed of up to 100 meters per minute can be achieved.

Potential applications for the coated materials are numerous. Optical layer systems are, for example, used for UV mirrors and as infrared-reflecting heat protection layers. Electromagnetic decoupling layers (EMI layers) and transparent conducting layers are used for displays. Flexible solar cells require front and back contacts or transparent conducting layers which are applied to polymer films.

The coFlex® 600 has a pre-treatment unit, optical in-situ measuring units, and several coating chambers. Thus, at Fraunhofer FEP we have a complete system for the development and pilot production of multilayer systems under realistic production conditions at our disposal.

Technical specifications

| Deposition width | 600 mm |

| Web width | 650 mm |

| Web thickness | 7 ... 200 µm |

| Max. external diameter | 400 mm |

| Web speed | 0.1 ... 100 m/min |

| Process modules |

|

| Coating material | Metals, TiO2, SiO2, Nb2O5, ITO, ZAO, SnO2, HfO2, WO3, TiN, Si3N4, ZrO2, ... |

| In-situ monitoring |

|

Technologies

- Pulse magnetron sputtering:

- dual magnetron sputtering

- unipolar magnetron sputtering

- DC sputtering

- Magnetron PECVD

- In-line pre-treatment

Our offer

- Development of technologies for coating polymer films and other flexible materials and development of plasma pre-treatment processes

- Development of layer systems (optical, electrical, and decorative functional layers, barrier layers)

- Development and testing of key components

- Sample provision for testing and marketing purposes, and pilot production

- Studies on the efficiency of coating processes

Fraunhofer Institute for Electron Beam

Fraunhofer Institute for Electron Beam