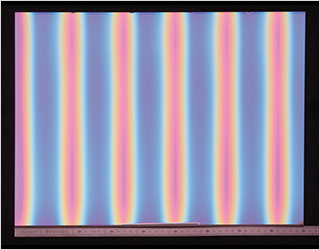

Sputtering technologies are one of the core technologies of Fraunhofer FEP. They enable the efficient deposition of layers and multilayer systems in a vacuum on large surfaces. Sputtering processes are particularly suitable for the precise deposition of thin, electrical and optical functional layers on an industrial scale. These processes guarantee layer thickness precision, low roughness and high layer adhesion.

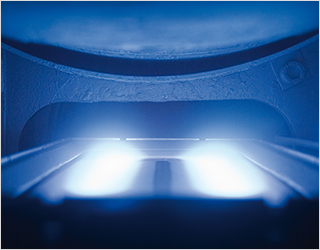

Our institute specializes in pulse magnetron sputtering (PMS) and the control of reactive sputtering processes. Interfering arcing processes can be minimized through the pulsed injection of electrical energy during the magnetron gas discharge. The reactive process control extends the range of materials that can be deposited, so that oxides, nitrides and oxynitrides can also be applied in addition to metals.

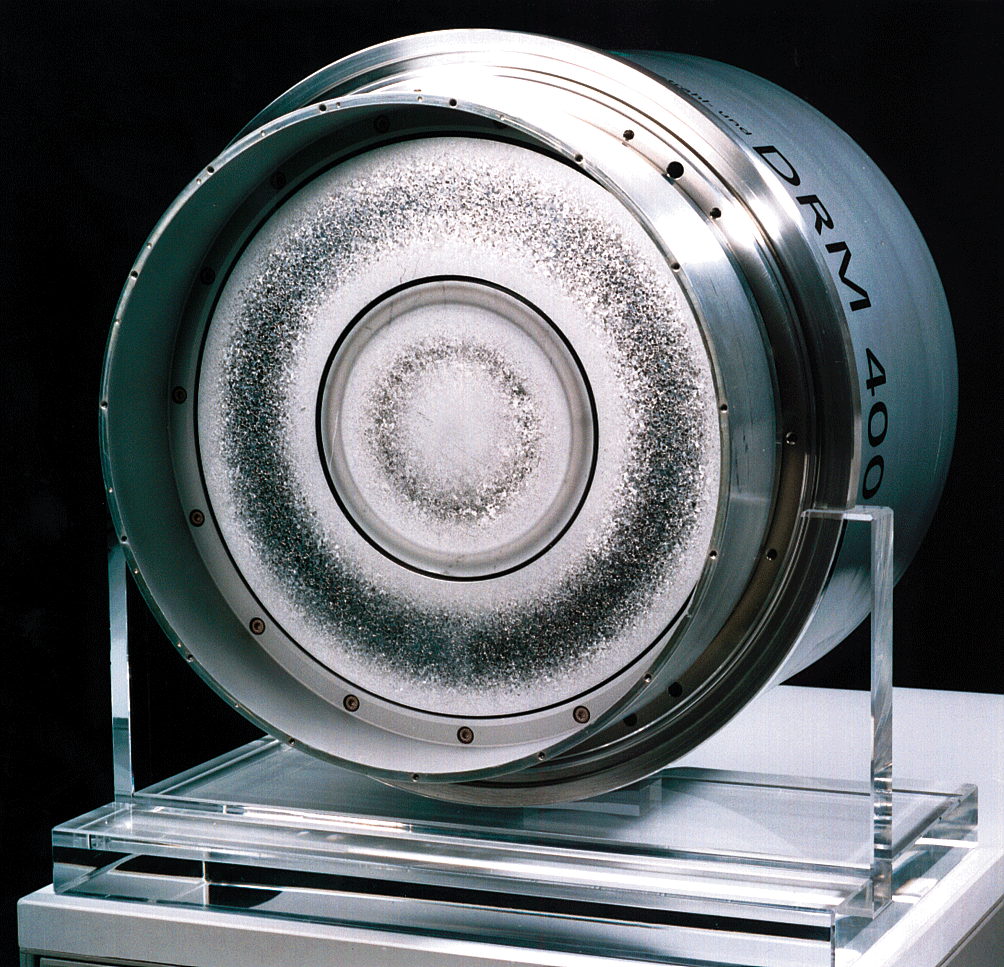

The dual magnetron sputtering system (DMS) can be used to deposit highly electrically insulating materials.

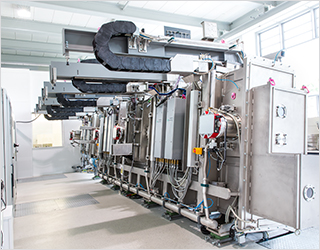

The Fraunhofer FEP utilizes and develops sputtering methods to provide innovative solutions for complex coating requirements. This includes the application of functional layers in sheet-to-sheet and roll-to-roll processes as well as on 3D components.

- Specialization in pulse magnetron sputtering (PMS) and reactive sputtering processes

- Application opportunities for metals, oxides, nitrides and highly insulating materials

- Innovative solutions for various coating requirements and technologies

Fraunhofer Institute for Electron Beam

Fraunhofer Institute for Electron Beam