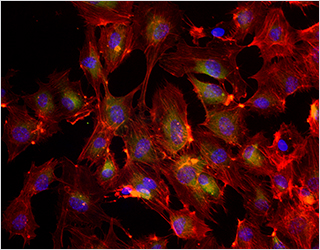

The modern biomedical laboratory complex of the Fraunhofer FEP with safety level S1 consists of laboratory units for microbiology, cell biology, bioanalytics as well as for surface chemistry and biotechnological reaction processes. This enables us to carry out interdisciplinary and industry-orientated research and development for a wide range of life science applications. We combine our technological core competences such as low-energy electron beam technology with medical-biotechnological applications. The laboratory unit fulfils all the requirements for biological safety level S2.

With our extensive laboratory and measurement technology, we offer customized solutions for various industries such as medical technology, pharmaceuticals, environmental technology and biotechnology. We combine technological expertise with practical application scenarios.

Fraunhofer Institute for Electron Beam

Fraunhofer Institute for Electron Beam