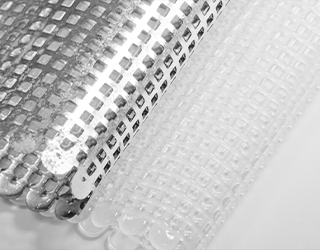

Suitable surface preparation is required for all surface processes (e.g. coating, welding, soldering, gluing, structuring, sterilization) require suitable surface preparation

- Removal of impurities (substances that interfere with the subsequent process)

- “Activation” of the surface (high adhesive forces, special bonding conditions)

- The type of surface pre-treatment is closely linked to the type of contamination and the subsequent process

Many cultural heritage objects are severely damaged by environmental influences, use or extreme events

- Modern surface technologies can be used to recreate lost objects

- Fragile objects must be stabilized

- Special cleaning technologies are required for fragile surfaces

- Complex damage patterns require new restoration methods

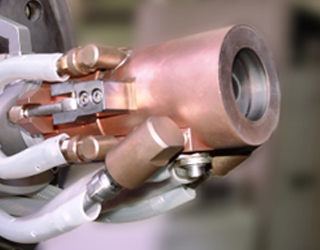

Fraunhofer Institute for Electron Beam

Fraunhofer Institute for Electron Beam