MAXI

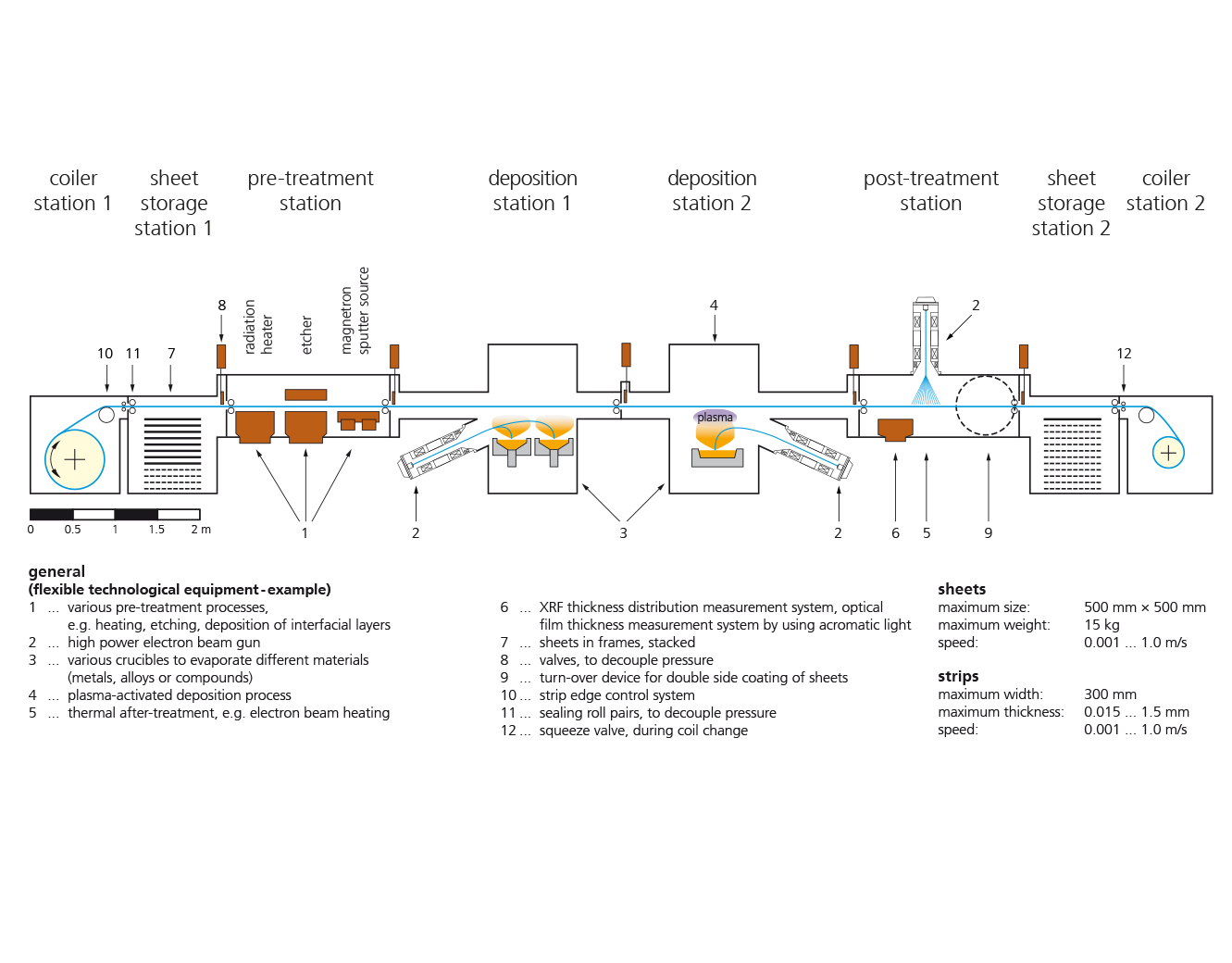

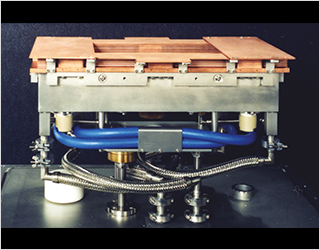

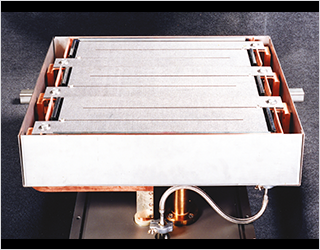

The "MAXI" in-line vacuum coating system for sheets and metal strips from Fraunhofer FEP offers a state-of-the-art solution for the efficient coating of thin metal strips and sheets.

It overcomes challenges such as plastic deformation and critical tensile loads through special pre-cleaning, pre-treatment, cooling and post-treatment. The system enables the precise deposition of thin films in a continuous process, ensuring high production speeds and consistent quality.

The combination of vacuum technology and advanced coating processes means that a wide range of materials can be optimally processed. The MAXI system also offers flexibility in adjusting the coating parameters to meet the specific requirements of different applications.

Ideal for industry and research, this technology contributes to the development of new products and applications. Discover the possibilities of the MAXI system and benefit from state-of-the-art coating technology.

Coating processes

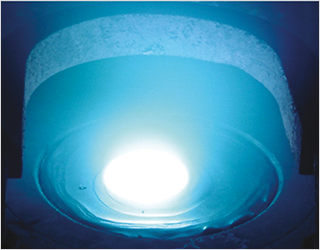

- High-rate electron beam evaporation

- Evaporation of metals, compounds, alloys

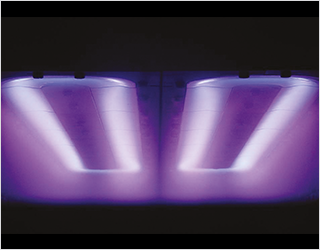

- Plasma-activated deposition processes (SAD and HAD)

- Reactive deposition processes

- Pulse magnetron sputtering

- Other PVD processes (e. g. jet evaporation)

- PECVD processes

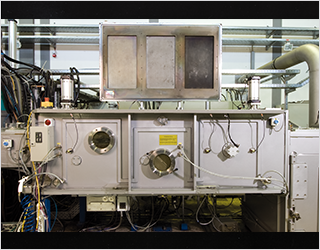

Technical specifications

| General | modularly built 8-chamber equipment |

| General dimensions | length / width / height: 14 m / 2.5 m / 4m |

| Coating width | up to 500 mm |

| Substrate speed | 0.001 … 1.0 m/s |

| Strip dimensions |

|

| Sheet dimensions |

|

| 1st electron beam gun | power maximum 160 kW |

| 2nd electron beam gun | power maximum 300 kW |

| Additional equipment |

|

Applications / Functions

| Corrosion-resistant coatings | ZnMg, Ti, Al, Cr, Cu, Sn, Zn |

| Decorative coatings | TiN, Cr, Ti, TiO2 |

| Transparent abrasion-resistant coatings | SiOX, Al2O3 |

| Hard coatings | TiN, TiC, a-C, WC, Al2O3, a-C(:H) (:Ti/W) |

| Insulating coatings | SiOX, Al2O3 |

| Conductive coatings | Al, Cu, Sn, Mo |

| Brazing and welding layers | Cu, Sn, Si |

| Photo catalytic layers | TiO2 |

| Solar absorption layers | Ti- or Cr-based cermets |

| Conversion layers | SiOX |

| High-reflective layers | SiO2, TiO2 |

| Special function layers | Al, Cu, Sn |

Fraunhofer Institute for Electron Beam

Fraunhofer Institute for Electron Beam