Life sciences are highly relevant to society and cover a wide range of areas. They address the major challenges of our time and are not only research-driven, but also strongly application-oriented, with enormous significance for health, the environment, agriculture, and industry. Life sciences are therefore a highly dynamic field that significantly shapes and advances both research and industrial applications through interdisciplinary collaboration and technological innovations. Fraunhofer FEP offers a wide range of technologies and processes for innovative solutions in key life sciences disciplines such as biotechnology, medicine and medical technology, pharmacy, agricultural, nutritional, and environmental sciences.

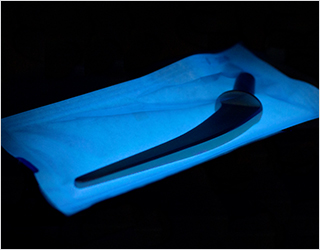

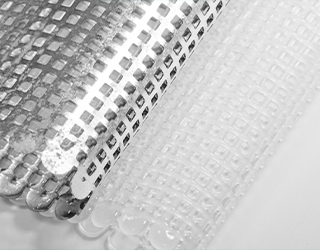

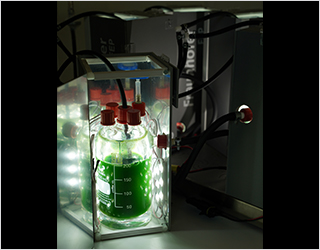

The life sciences research and development work carried out by Fraunhofer FEP is characterized by the establishment of gentle, chemical-free, and sustainable processes. The wide range of applications, from medical technology and biotechnology to environmental technology, is made possible by the versatility and scalability of the core competencies in electron beam and plasma technology. Synergies with biotechnological processes lead to the development of new hybrid technologies.

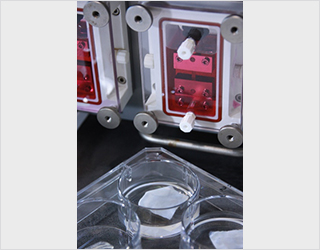

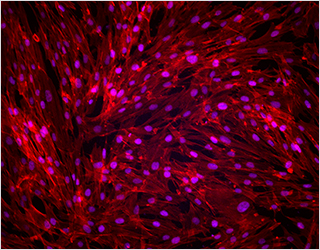

Fraunhofer FEP sees itself as a platform that can combine comprehensive technological expertise with application-relevant evaluation scenarios for medical technology and biotechnology issues through its biomedical laboratory unit consisting of microbiology, cell biology, and bioanalytics in accordance with QM guidelines (DIN ISO 9001). This enables interdisciplinary and industry-oriented research and development for a wide range of life science applications.

We look forward to working with you to evaluate how we can qualify our technologies and processes for your research and development requirements. Interdisciplinary collaborations play a central and indispensable role in the development of innovative solutions at Fraunhofer FEP, especially in life science applications.

Fraunhofer Institute for Electron Beam

Fraunhofer Institute for Electron Beam