The Materials analysis department at Fraunhofer FEP has a wide range of methods at its disposal for characterizing thin films and surfaces. The methods and extensive analytical experience of our employees are available for product and technology development within our institute and as a service for our customers. Typical fields of application are coatings for optics, sensor technology, displays, photovoltaics, packaging, corrosion and wear protection.

Materials analysis

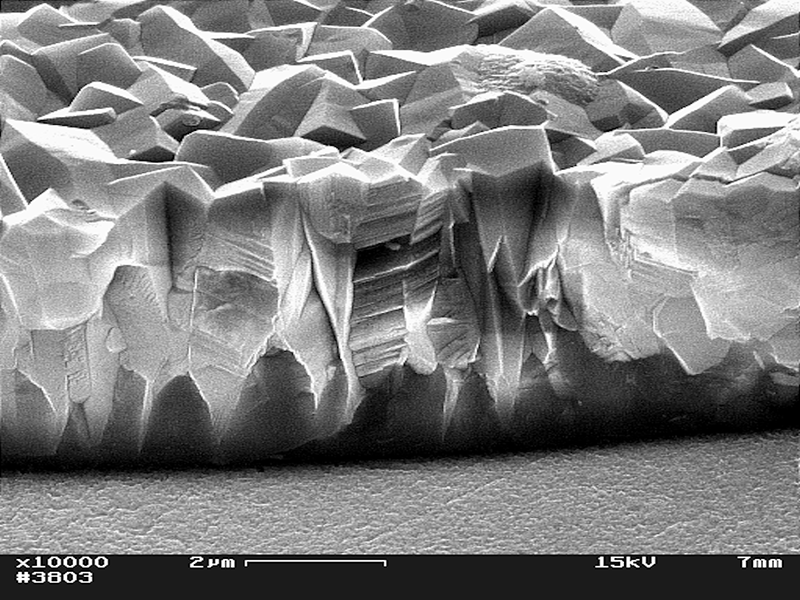

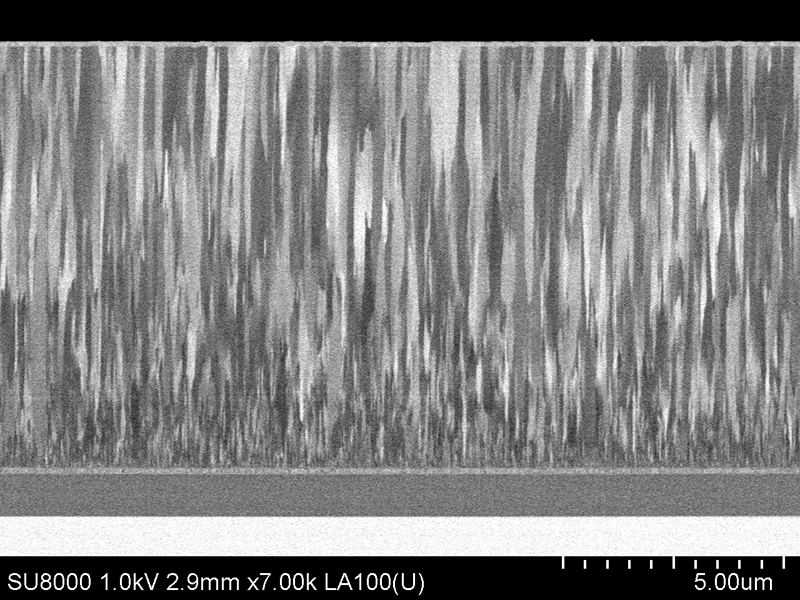

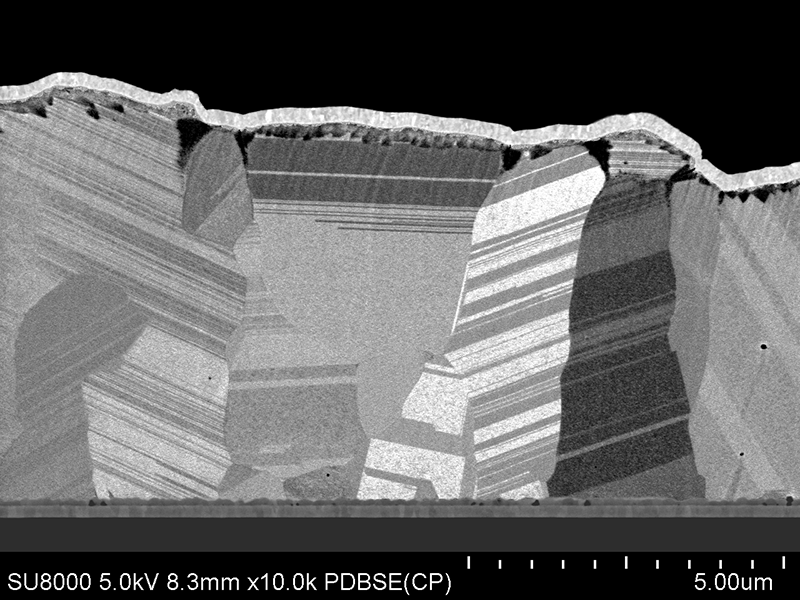

Structure and microstructure

- High resolution field emission scanning electron microscope (FE-REM), SU8000 (Hitachi)

- Ion preparation of cross sections (BIB), Cross Section Polisher SM-09010 (JEOL)

- Metallographic preparation technique (Struers) and light microscope Polyvar 2 Met (Reichert)

- X-ray diffraction (XRD), D8 Discover (Bruker)

Phase analyses, film stress, rocking curves, texture analyses with pole figures

Chemical composition

- Energy dispersive spectrometry of X-rays (EDS), SDD detector Octane Elect (EDAX)

- Optical glow discharge spectrometry (GD-OES) for measurement of chemical depth profiles, GD-Profiler 2 (HORIBA Jobin Yvon)

Topography, surface and layer thickness

- Atomic force microscopy (AFM), NX-20 (Park Systems) for investigation of roughness and further physical properties with high lateral resolution (Piezo Force Microscopy, Conductive AFM, Kelvin Probe Froce Microscopy)

- Profilometry, P15-LS (Tencor)

- Calotest (CSEM)

- Contact angle, OCA 20 (Data Physics)

Optical, mechanical and electrical properties

- Spectroscopic ellipsometry SE850 (SENTECH)

- UV/VIS/NIR spectroscopy, Lambda 950 (Perkin Elmer)

- Light scattering, Haze-guard plus (BYK-Gardner)

- Hardness and modulus of elasticity, Nano Indenter XP (MTS)

- Layer stresses, Profilometer P15-LS (TENCOR)

- Adhesion strength by scratch test, MST4 (CSEM)

- Abrasion resistance (Taber Abraser)

- Four point measuring station FPP 5000 (Veeco) with 2400 Sourcemeter (Keithley)

- Measurement of electrical resistance of isolating layers (SÜSS Prober with Keithley 6487 Picoammeter)

Corrosion and climate tests

- Corrosion test system for condensation water (DIN EN ISO 6270-2) and salt spray test (DIN EN ISO 9227), SKB 400 A-SC (Liebisch)

- Climate chamber - 40 ... 150 °C with adjustable humidity, SH-241 (ESPEC), e.g. environmental test methods (DIN ISO 9022-2)

Permeation barrier

- Water vapour transmission rate (WVTR) according to DIN EN ISO 15106-03,

- WDDG (Brugger Feinmechanik); Measuring range 1 × 10-3 to 10 g/(m2d)

- Aquatran Model 3 (Mocon), Measuring range 1 × 10-4 to 5 g/(m2d)

- Water vapour permeability, HiBarSens 2.0 HT (Sempa);

Measuring range 1 × 10-5 to 10-2 g/(m2d) - Oxygen permeability (OTR) according to DIN 53380-3, ASTM D 3985-05, ASTM F 2622-08 and ISO 15105-2

- OX-TRAN 2/20 (Mocon); Measuring range 0.1 to 200 cm3/(m2d bar)

- OX-TRAN 2/12R (Mocon); Measuring range 0.05 to 28800 cm3/(m2d bar)

Fraunhofer Institute for Electron Beam

Fraunhofer Institute for Electron Beam