Experimental equipment for modifying organic materials using accelerated electrons

The REAMODE equipment uses an electron beam to modify surfaces for a variety of applications and to sterilize /disinfect surfaces and products.

The equipment parameters can be adjusted in order to control the penetration depth of the electrons and the intensity of the electron beam. This allows materials to be modified in a customized way.

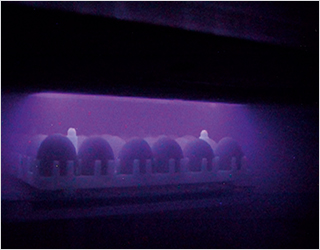

For example, lacquers can be efficiently cured, polymer surfaces can be modified and crosslinked, and products can be disinfected or sterilized. The equipment has three different transport modules that allow treatment of substrates with 2-D or 3-D geometries, as well as bulk goods.

The substrates can be processed in the equipment under atmospheric pressure, under protective gas atmosphere, and under reduced pressure.

| Electron beam source UV beam source – UMEX |

max. 2,5 kW bei 200 kV max. 3,0 kW |

| Penetration (treatment) depth | 10 ... 200 μm |

| Dynamic dosing | max. 10.000 kGy × mm/s |

| Usable chamber size (W × H × D) Max. electron beam source flange dimensions |

900 × 1100 × 1300 mm 1000 × 800 mm |

| Modular equipment concept • rapid module and sample change • adaptable and extendable |

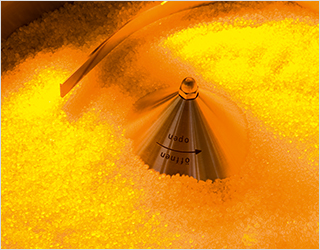

Linear transport module for 2-D and 3-D • product samples up to 300 × 400 × 300 mm • substrate speed 0.05 ... 2 m/s • load capacity of substrate platform max. 5.0 kg Rounding module for bulk goods with • particle sizes > 500 μm • speed range 200 ... 1000 rpm • filling quantity (max. 3.0 kg) Robot arm for 3-D substrates • load capacity: max. 5.0 kg • substrate size up to 350 × 230 × 100 mm |

| Prozessbedingungen | Different atmospheres, vacuum Process gas (air, CO2, N2), inert gas (Ar) Treatment temperature max. 360°C |

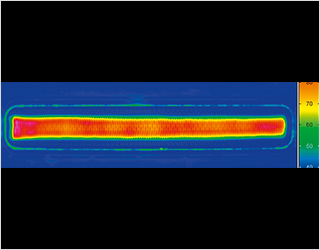

| Prozessmesstechnik | High resolution IR thermography Various dosimetry systems Optical high dose measurement up to 5000 kGy Online beam monitoring |

| Process data acquisition and accompanying process and product analysis, temperature monitoring and control (chamber, substrate) | |