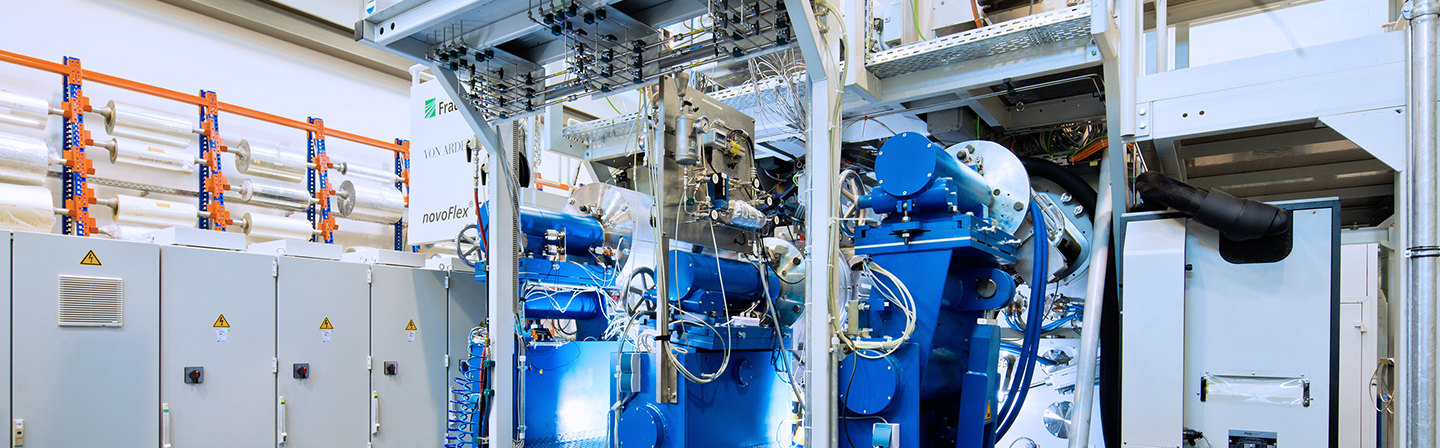

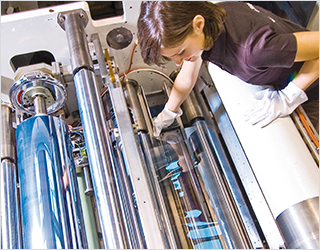

Roll-to-roll pilot web coater – novoFlex

The novoFlex® 600 pilot web coater allows coating of polymer films with different materials in any desired sequence.

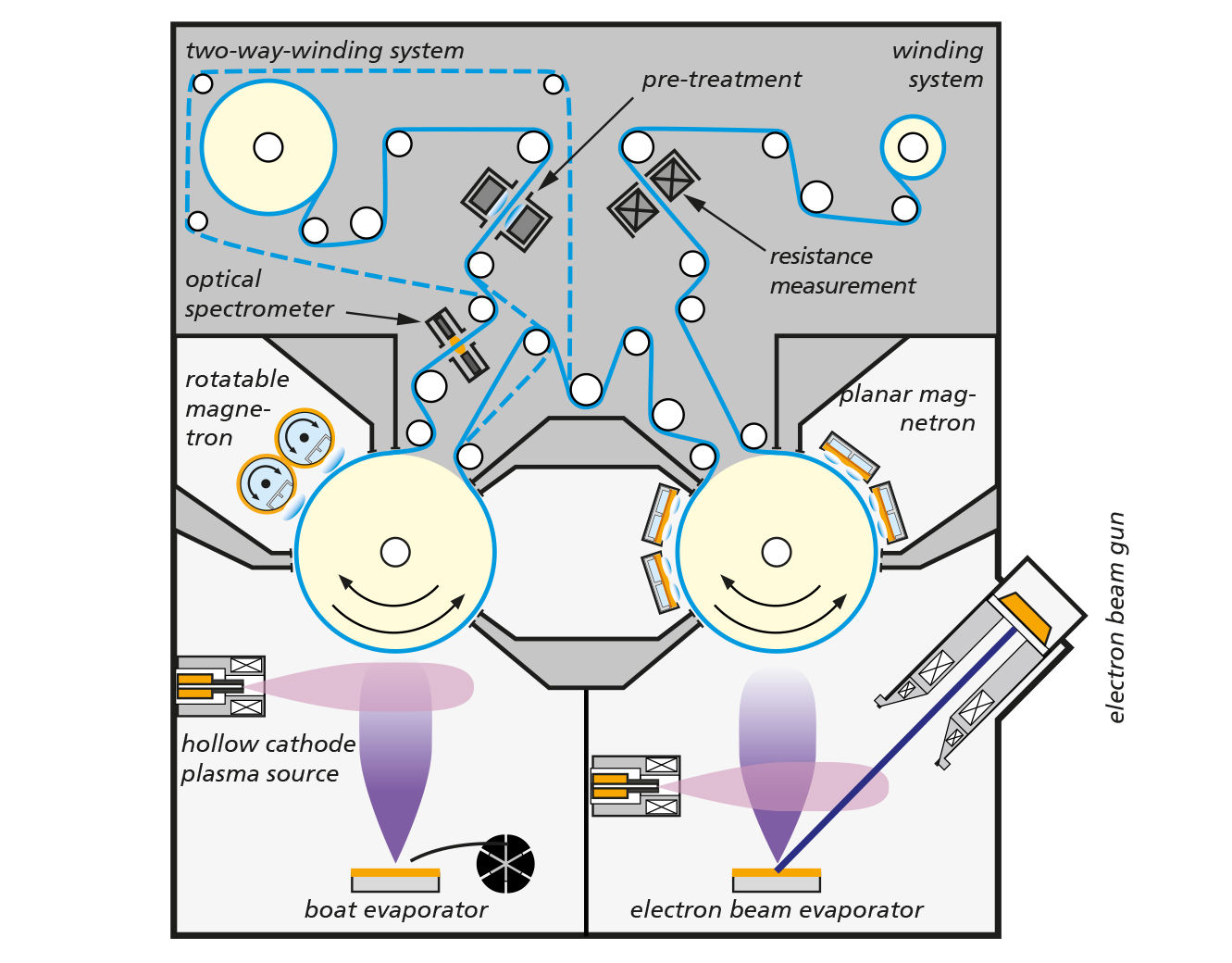

The web coater includes various vacuum coating technologies which can be combined with each other in different ways. This versatility means that a wide range of coatings and layer combinations can be created.

Customers can also choose from a wide variety of substrates: In addition to polymer films made of PET, polypropylene (PP), and polylactides (PLA), the web coater can also be used to test and coat customer-specific polymer substrates, flexible metals foils and textiles.

The application of barrier layers to packaging films for the food industry is one established area of work. The main benefit is the very high coating rate in order to coat large quantities of film at favorable cost.

The web coater can also be used to apply layers for special applications, for example transparent conducting electrodes and high barrier layers for flexible electronics.

Technical specifications

| Coating width | ≤ 600 mm |

| Web speed | 0.1 ... 600 m/min |

| Web tension | 30 ... 1500 N |

| Substrates |

|

| Maximum roll diameter | 500 mm |

| Maximum range of the web edge control | ± 10 mm |

| Subdivided into 5 coating chambers for simultaneous coating using up to 5 in-line processes | |

|

|

| 2 coating drums of 750 mm diameter, each with separate temperature control in the range -20°C ... +90°C | |

| In-situ measuring technology |

|

Technologies

- In-line plasma pre-treatment

- Plasma-activated high-rate evaporation

- Pulse magnetron sputtering (PMS)

- Magnetron PECVD (magPECVD)

- Thermal evaporation

- Electron beam evaporation

- In-situ measurement technology

- Hollow cathode arc PECVD (arcPECVD)

Our offer

- Feasibility studies

- Development of layer systems, products, and coating technologies for vacuum web coating

- Scale-up of coating technologies to large web widths and high web speeds

- Contract coating in the pilot phase of a product

- Technology transfer and fitting web coating plants with key components (magnetrons, plasma sources, reactive gas systems, product and process monitoring systems)

Fraunhofer Institute for Electron Beam

Fraunhofer Institute for Electron Beam