The packaging sector is subject to enormous cost pressure: packaging material must not usually cost much, but is very important for the quality and shelf life of the end product.

In addition, the demand for packaging materials is constantly increasing. In contrast, the amount of materials based on fossil raw materials must be reduced in order to contribute to a sustainable future. The proportion of renewable, bio-based materials for packaging products must increase in order to avoid environmental pollution, e.g. through microplastics.

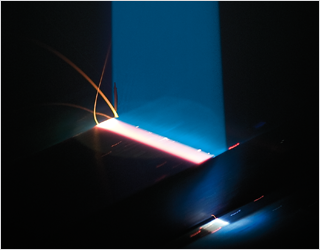

Technologies for vacuum coating and surface modification with electrons from the Fraunhofer FEP are ideally suited to this task due to their high productivity and the very good surface properties that can be achieved.

Based on our technological expertise, we offer in particular the functionalization of bio-based and biodegradable films as well as monomaterials, for example for permeation barriers to extend the shelf life of the product. We also use electron beam technology to modify the surface of plastics or to cure printing inks or lacquer-based functional layers.

We support you with the development of highly productive technologies and processes for the finishing of your packaging!

Fraunhofer Institute for Electron Beam

Fraunhofer Institute for Electron Beam