23 | 2017 – Lightweight, compact VR glasses made possible by large-area microdisplays

VR glasses are increasingly popular, but they have usually been heavy and oversized – until now. Large-area microdisplays are expected to change that, because they make it possible to produce ergonomic and lightweight VR glasses. The new OLED displays now reach very high frame rates and achieve extremely high resolutions with “extended full HD”.

The image is crystal clear, and you feel as if you are really walking through the incredible worlds that your VR glasses are conjuring up around you. Until now, however, these glasses have usually been rather heavy and bulky. That is mainly due to the display, which is the key component in every pair of VR glasses. Commercially available VR glasses generally use displays designed for the smartphone market. These displays are cheaply available and employ simple optics to provide a wide field of view. The disadvantage is that they produce pixelated images because of their limited resolution and insufficient pixel density. Modulating LCD and LCOS microdisplays are also used. These are not self-illuminating, however, which means an external light source is necessary. In order to produce VR glasses that are light and ergonomic, some manufacturers are therefore already focusing on OLED microdisplays. These are based on organic light-emitting diodes, which are integrated onto a silicon chip and are selfilluminating. As a result, they are energy-efficient and yield very high contrast ratios >10 000:1. In addition, the fact that there is no need for a backlight means that they can be constructed in a simpler fashion, with fewer optical components. Another advantage is the fast switching speed of OLEDs, which is around a few microseconds as against milliseconds in the case of LCDs. This enables high frame rates as well as achieve high frame rates as well as to employ special modulation processes to improve the perceived image.

Compact design and high resolution

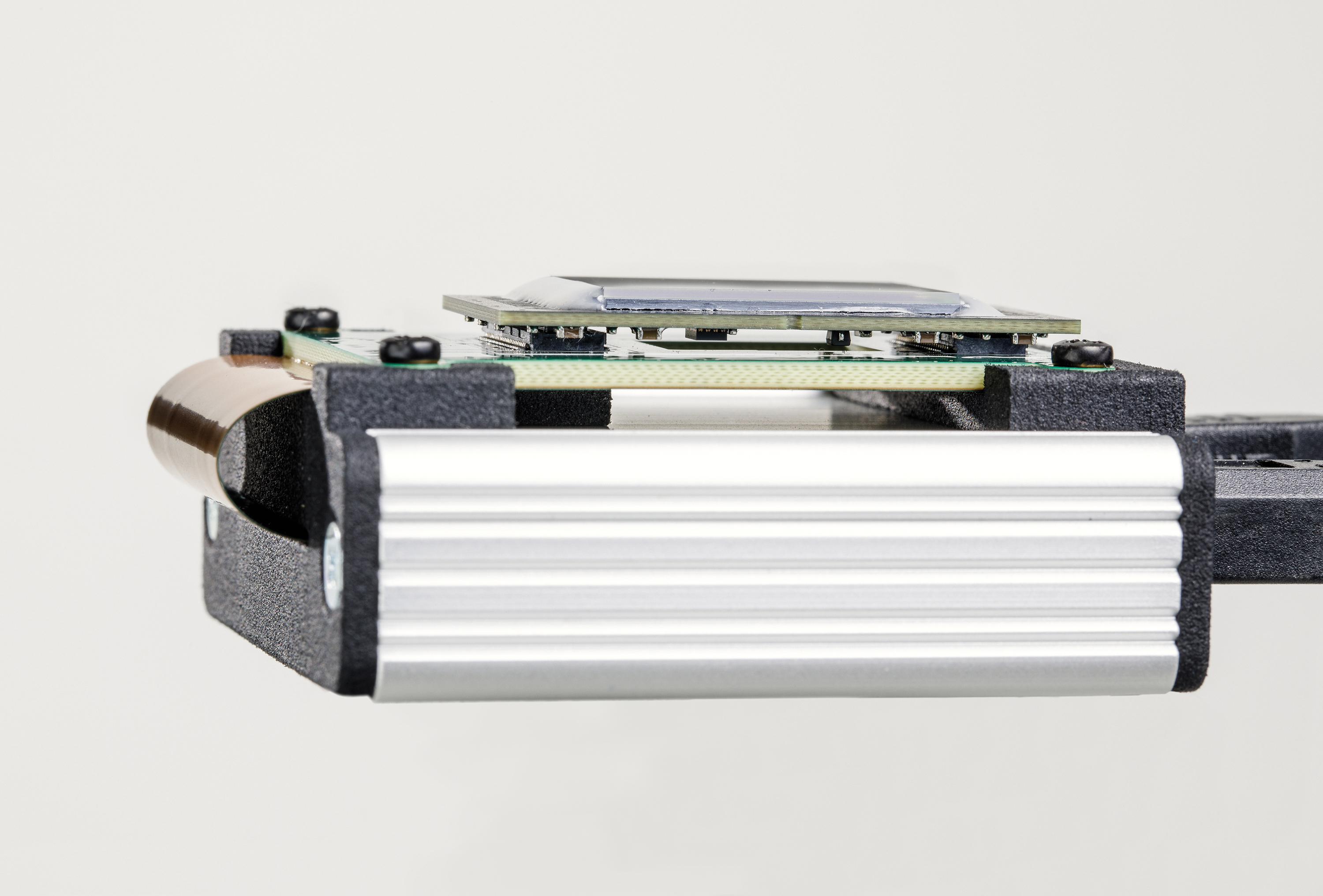

As part of the EU’s LOMID project – an acronym for large cost-effective OLED microdisplays and their applications – researchers at the Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP in Dresden have been collaborating with partners from industry to develop innovative OLED microdisplays that significantly outperform others currently on the market. Within LOMID, Fraunhofer FEP is responsible for designing the integrated circuit on the silicon chip, creating OLED prototypes, and coordinating the whole project. Philipp Wartenberg, head of department at Fraunhofer FEP, says, “Our goal is to develop a new generation of OLED displays that provide outstanding picture quality and make it possible to produce VR glasses in a compact format. We aim to achieve that by means of a specially designed OLED microdisplay.” So far, so good. However, what is so special about the microdisplays that are being developed within the project? One answer to that is their resolution: they achieve extended full HD, which means they have a resolution of 1920 × 1200 pixels (WUXGA). The diagonal screen size is about one inch, and the frame rate is around 120 Hertz. That means 120 images are displayed every second, which makes movements in the virtual world seem very fluid indeed.

Specially designed circuits on the chip

Two components make up the microdisplay: a silicon chip to control the pixels, and an OLED. This OLED consists of several organic layers, which are monolithically integrated on silicon wafers. The microdisplay’s resolution and frame rate are set by the chip with the help of its integrated circuit. However, the really innovative feature is the type of circuit that is used. “The trick isn’t just to raise the resolution and frame rate, but also to keep power consumption to a minimum at the same time,” says Wartenberg. “We’ve been very successful at that thanks to a cleverly designed system concept and modern design methodology, not to mention our more than ten years of experience at Fraunhofer FEP in designing OLED microdisplays.”

The researchers have already made their first prototype, which they will be presenting in Brussels from December 5 to 7 at the European Forum for Electronic Components and Systems 2017 (EFECS). Further prototypes are due to follow by the middle of 2018. Industry partners involved in the project have already indicated their interest in converting this microdisplay into a marketable product in the near future. In this respect, the use of OLED microdisplays is by no means limited only to VR glasses – even though this may well be the largest market in the medium-term. OLED microdisplays are also suitable for other products such as augmented reality (AR) glasses or view finders in cameras. The underlying technology of CMOS-integrated light emitters (and any detectors) also has potential uses in other market segments such as optical metrology and identification, or optogenetics.

Especially with regard to microdisplays in consumer-facing augmented reality glasses, the researchers still see some as yet unresolved challenges that they wish to tackle in the future. These challenges include: very high levels of luminance and efficiency (which will necessitate removing the color filters used until now, and replacing these with directly structured emitters); a high yield for a large (chip) area; curved surfaces for more compact optics; circular light panels; irregular pixel matrices at even higher pixel density; integrated eye tracking; and transparent substrates.

Contact:

Philipp Wartenberg

philipp.wartenberg@fep.fraunhofer.de

Phone +49 351 8823-386

Last modified:

Fraunhofer Institute for Electron Beam

Fraunhofer Institute for Electron Beam