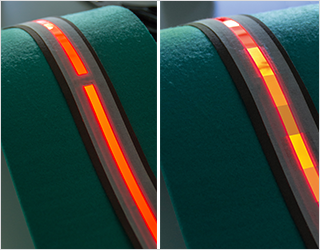

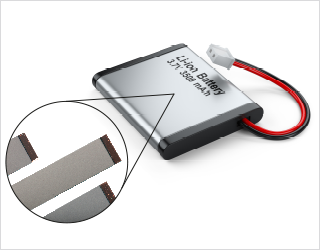

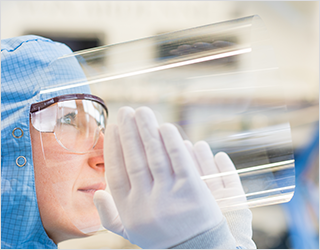

The recently launched KODOS project (“Konfektionierter Dünnglas-Verbund für optoelektronische Systeme”, Thin Glass Composites for Optoelectronic Systems), funded by the German Federal Ministry of Education and Research, is designed to transform thin glass into finished products along the entire value chain. The companies EMDE development of light, Volkswagen and Deutsche Werkstätten Hellerau, which focus on application development, have joined forces with the technology suppliers tesa, VON ARDENNE, Flabeg, 4JET microtech, SURAGUS, and the Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP. The aim of the consortium is to be able to offer a complete modular system of functional materials, semi-finished products, tools, and technologies for the roll-to-roll production of optoelectronic systems on thin glass.

more info Fraunhofer Institute for Electron Beam

Fraunhofer Institute for Electron Beam