Dear partners of the Fraunhofer FEP,

Dear readers,

2023 was a crisis-ridden year globally that brought many major challenges – from political turmoil and conflict to natural disasters – that culminated in diverse and complex economic uncertainty. However, despite all the hurdles, we at Fraunhofer FEP can look back on many positive developments as many of these external challenges presented opportunities.

Our outstanding energy management system and years of forward-looking conversion to sustainable energy supply solutions, such as photovoltaic modules for autonomous electricity production, use of waste heat from our large machines for heating office and lab space and smart solutions for local energy saving, have helped us get off to a good start this year despite rising energy prices. Thanks to the successful acquisition of numerous industrial projects and publicly funded projects by the FEP team, we were able to achieve a balanced economic result for the year.

In April we presented the institute strategy to external auditors from industry, academia, and politics. Regular strategy reviews are standard practice in the Fraunhofer Society. Preparations began in the fall of 2022 and involved several workshops that integrated the interdisciplinary teams and individual business units of the institute. The strategy report included the overarching institute vision and focus on sustainability, human resources, digitalization and scientific excellent. In addition, the business units Plasma Technology, Electron Beam Technologies, and Medical Biotechnology Applications presented detailed strategic plans. The strategy audit in 2023 kicked off continuing process in which the Fraunhofer FEP will monitor and re-examine the strategic focus of the institute annually, with a larger strategy audit every 5 years. In a very constructive exchange with the external consultants and auditors, our strategic focus was confirmed and the tools for future strategy evaluations were defined. In future, we will build on this audit for the ongoing strategic review of the institute. We would like to thank all colleagues involved, our external consultants and auditors for their support and the constructive discussion. As a result, we at Fraunhofer FEP will build on our existing strengths and unique selling points and to strategically position the institute towards current and emerging markets.

Our technological developments – particularly in the field of coating flexible products such as films or ultra-thin glass – are increasingly being used in sustainable construction applications. We have been able to lay important foundations within several EU projects, including the development of thermochromic and electrochromic coatings for the building sector. The first prototypes of smart windows, as a contribution to reducing energy consumption in buildings, and hydrophilic coatings on ultra-thin glass from the Switch2Save, NewSkin and FLEX-G 4.0 projects met with a very positive response at our first participation at the BAU 2023 trade fair in Munich. In addition to the publicly funded projects, continuous research and development with leading industrial partners is leading to further pioneering advances in the field of sustainability.

After the first years, the sputter epitaxy working group at Fraunhofer FEP has established itself. For the second time, our institute organized an online workshop with numerous international experts and offered a platform for the exchange of current research results. We look forward to further developing our technological platform and network of partners in this field in coming years.

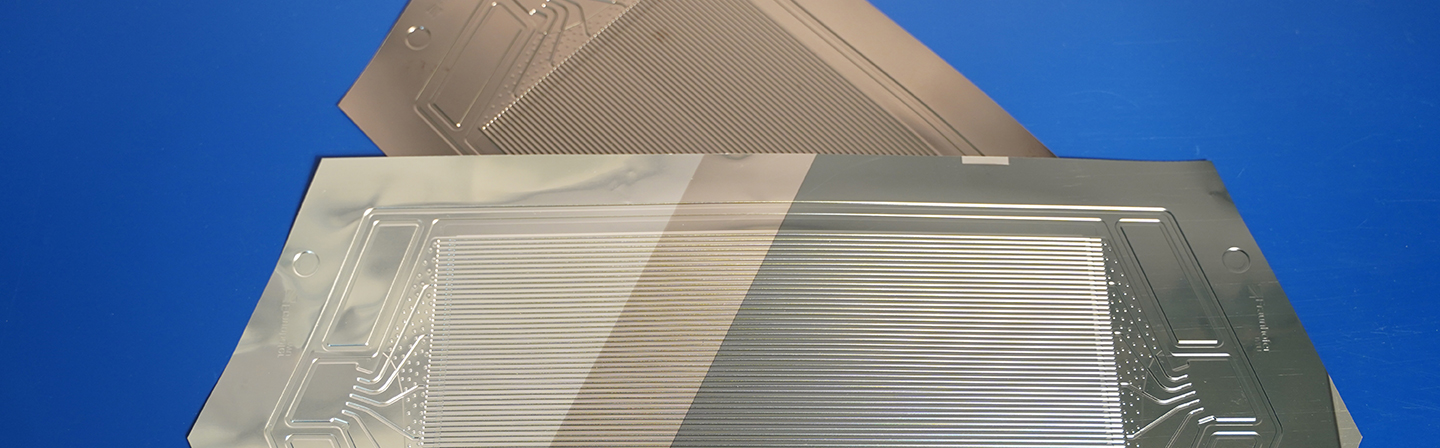

We see incredibly potential for our vast and unique expertise in the development of electron beam technologies for application in hydrogen technologies to support the energy transition. As an example of one of the many activities in this direction, we coated the first bipolar plates last year and optimized our system technology for this purpose. Our range of technologies for the production, storage and processing of hydrogen for the energy transition was presented very actively as part of our networking activities, e. g. in the Fraunhofer hydrogen network or with the Saxon cluster HZwo e.V., and also presented for the first time at regional and international conferences and trade fairs in Dresden and Brussels.

For a few years now, the Fraunhofer FEP is responsible for the Fraunhofer-business area Cleaning. This year was a special one for all members. Fraunhofer-business area Cleaning celebrated its 20th anniversary. The celebrations culminated at parts2clean with numerous activities and technical presentations as well as an anniversary breakfast.

The institute announced another highlight in the summer. Within the "Backplane" project funded by the Saxon State Ministry of Economic Affairs, Labor and Transport SMWA , colleagues from the Microdisplays and Sensors department realized OLED microdisplays in a 28-nanometer backplane technology on 300 mm wafers for the first time. This made it possible to produce components with a display diagonal of 0.18 inches and pixel sizes of just 2.5 micrometers. This corresponds to an as-yet unattained level in the global OLED microdisplay market and is world record.

Our expertise in the field of medical and biotechnological applications using the diverse effects of electron beams once again contributed to many projects in 2023. The expansion of our S1/S2 facilities to validate these processes and technologies are now possible in the new laboratories in our newly completed building that will house activities for electron beam technologies for environmental, medical, ecological, and sustainable applications. In order to create a solid basis for these activities, organizational adjustments were made to enhance the synergistic potential in the institute. We are using the momentum of this eventful year to start 2024 with the official inauguration of the new building on the RESET (Resource Saving Energy Technologies) campus next spring.

I would like to thank all our employees as well as our funding bodies and industry and academic partners for their continued great trust, support, and cooperation and a fantastic year in the face of the numerous external challenges we faced together!

In our annual report, we take a detailed look at the highlights of the last twelve months. I hope you enjoy reading it and look forward to continuing our good cooperation!

Fraunhofer Institute for Electron Beam

Fraunhofer Institute for Electron Beam