The aim of the “SanFlex” project is to reduce healthcare-associated infections by developing antipathogenic coatings based on crystalline TiO2 thin films enhanced by a super-acidic surface, applicated on flexible substrates for touchscreens and displays.

JEvery year, approximately 4 million people acquire healthcare-associated infections in Europe1. Pathogens spread quickly via surfaces such as handrails, handles or touchscreens. To reduce the spread of pathogens, particularly in hospitals but also in public buildings, the EU-funded project SanFlex is researching on photocatalytic titanium dioxide coatings that are additionally modified by a super-acidic surface.

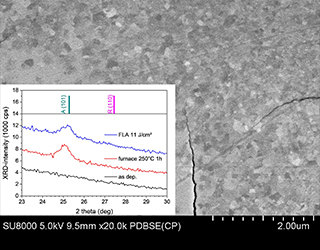

In the future perspective, the coatings shall be used on protective films for user interfaces such as touchscreens. The challenge is to produce the anatase-crystalline TiO2 layers required for functionalization on flexible substrates. To this end, Fraunhofer FEP is pursuing the approach of depositing the layers in the amorphous state using an established large-area inline magnetron sputtering process and afterwards crystallizing them in a post-annealing step using large-area inline flash lamp annealing (FLA). On the crystalline TiO2 facetes, inorganic acid groups are adsorbed via a photo fixation step, making the surface super-acidic. This modified surface has an antipathogenic effect in two respects: the attachment of pathogens is initially prevented and at the same time microorganisms on the surface are eliminated.

The proof of principle has been realized on rigid glass substrates. Therefore, the relationship between the layer deposition, the crystallization process by inline FLA and the photo fixation of the inorganic acid groups has been studied. The investigated process steps are characterized by an inline capability, which shall enable the production in a roll-to-roll process in the future. Based on the gained knowledge, the project is now in the transfer phase from rigid to flexible substrates. Initial successes have been achieved in the crystallization of TiO2 layers on temperature-stable polymer films.

Current work is focused on the correlation between the degree of crystallization and the photo fixation process. The thermal management of the crystallization process is also in the focus of investigations.

---

1 C. Suetens et al., “Prevalence of healthcare-associated infections, estimated incidence and composite antimicrobial resistance index in acute care hospitals and long-term care facilities: results from two European point prevalence surveys, 2016 to 2017”,

Eurosurveillance, 2018, vol. 23/46.

Fraunhofer Institute for Electron Beam

Fraunhofer Institute for Electron Beam