Fraunhofer FEP has developed a modular high-voltage power supply for electron beam processes that is compact and cost-effective. The prototype achieves 15 times the power density of conventional devices and can be scaled up to 600 kV.

Electron beam modules for innovative applications and current technological development projects at Fraunhofer FEP require a powerful, compact, flexibly configurable and cost-effective high-voltage technology. Commercially available high-voltage power supplies (HVPS) currently only meet these requirements to a limited extent.

The aim of the “HVdirect” project was to develop a modular HVPS that is designed for high-voltage applications up to 600 kV and can be integrated into an electron source. In addition to maximum compactness, minimal energy storage

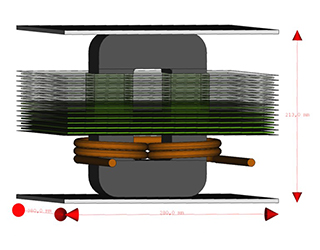

is required in the output circuit of the HVPS and in the connecting elements to the electron source in order to reduce damage caused by high-voltage flashovers (arcs) and undesirable process interruptions. Known HVPS concepts were initially evaluated for suitability and optimisation potential. The concept of the insulated core transformer proved to be the most promising.

Using modern simulation tools such as FEM, all high-voltage components (secondary winding of the transformer, magnetic flux compensation, rectification and frequency-accurate voltage measurement) were integrated directly onto PCB boards. Each board supplies 100 mA @ 10 kV and can be stacked in series as modules, depending on the voltage requirements of the application. A compact, modular demonstrator with 120 kV × 100 mA was constructed and combined with a resonant converter. Tests were carried out using a water resistor, which was also realised and proved to be a cost-effective and safe tool suitable for highly dynamic measurements. Good robustness was achieved through optical signal transmission, precise and fast power management using SiC semiconductor switches and FPGA control. The HVPS realised in this way achieves 15 times the power density of conventional devices.

Following further practical tests, the HVPS is ready for use as an independent system component in the low-energy range. The development result will be marketed with the FEP technologies as part of the Fraunhofer FEP's “Integrated Packages”.

Fraunhofer Institute for Electron Beam

Fraunhofer Institute for Electron Beam