High-performance coatings for effective use and storage of solar energy

Fifty-five percent of the final energy consumption in Germany are expended for heating and air conditioning. In order to reach climate neutrality by 2050, it is essential to avoid the use of fossil fuels for heating and instead rely on the number one energy supplier: the sun. In the domains of photovoltaics and solar thermal energy collection thin film systems contribute to the effective use of a broad spectrum of solar radiation, both for electricity generation and for heating. Vacuum technologies developed by the Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP are used to deposit layers and layer systems serving the exploitation of solar energy and the storage of heat on an industrial scale, contributing to the increased use of this important energy source.

The radiant energy that the earth receives from the sun within 90 minutes is roughly equivalent to the world's energy consumption during an entire year. (Source: AEE).

To effectively absorb solar irradiation, whether for photovoltaics or solar heat, specially designed and optimized coating systems are required. These include semiconductor coatings and electrode coatings in the field of photovoltaics. For solar thermal applications, absorber coatings with high absorption in the visible and ultraviolet (UV) spectral range and low emission in the infrared spectral range (IR) are required to keep losses caused by heat radiation low.

Effective solar absorbers through optimized coating systems

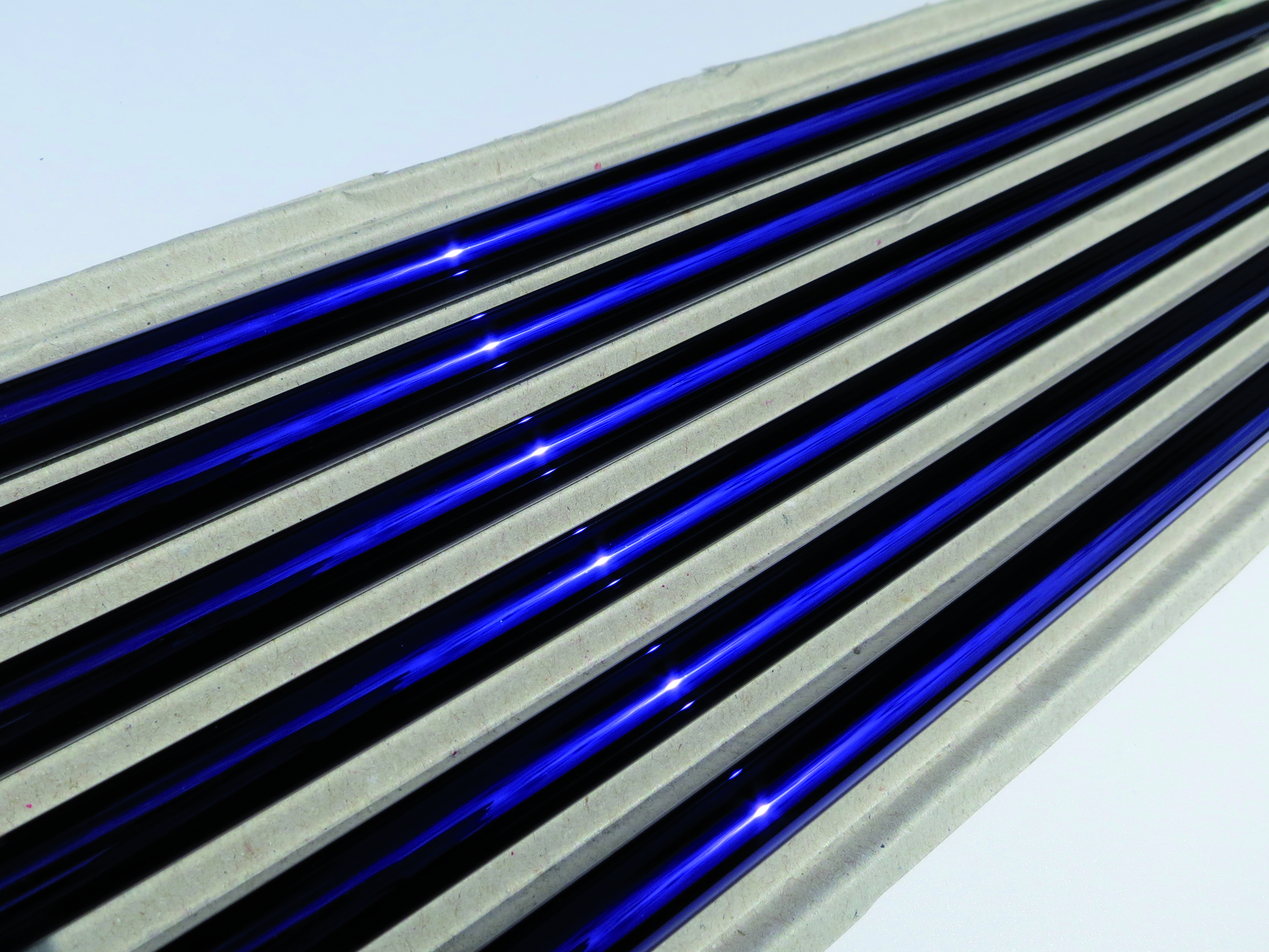

To realize such an optical function, a coating system must be created from several individual layers with precisely adjusted thickness which have to be deposited reproducibly on absorber tubes of vacuum tube collectors – the state of the art collector type with lowest heat losses. The absorber tube is embedded in an evacuated glass tube, so that the coating system is protected from contamination and any degradation caused by air constituents. Nevertheless, the coating system must withstand the high temperatures assumed by the absorber tube, and must also be stable on the long term under cyclic temperature loads. The higher the temperature in the heat cycle, the better and more diversely it can be used, either directly as process heat or to charge thermal accumulators at high temperatures.

Coatings also contribute to the development of more efficient storage systems. In order to make the energy provided by photovoltaics usable in a time-variable manner, extensive research is currently being carried out into electrical energy storage systems that are intended to compensate for the temporal offset between electricity generation and electricity consumption.

New coating processes for storage concepts with Zeolite-granules

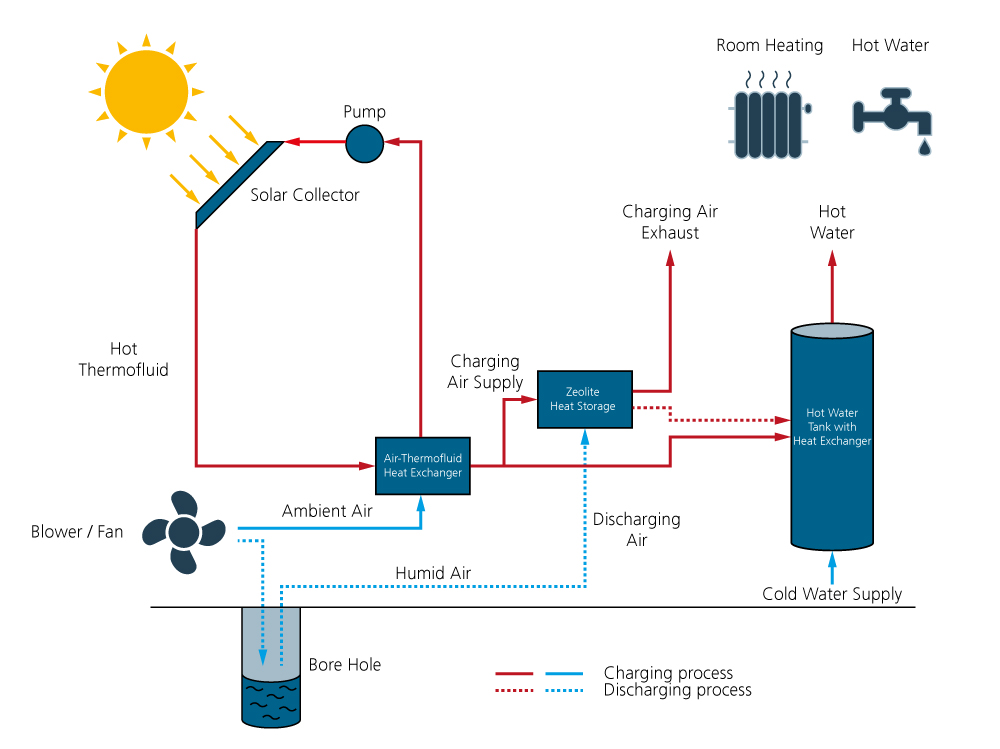

For the heat sector, this function is taken over by a water storage tank in many cases. But current R&D work focuses on better storage concepts having a higher storage capacity than water and allowing to save space and to reduce losses. These include adsorption heat storage systems in which water is expelled from nano-porous zeolite granules when dry hot air is fed through. This corresponds to the charging of the storage unit with energy.

“When water vapor-loaded air flows through the storage material, it adsorbs water, releasing heat that can be used in heat cycles” explains Dr. Heidrun Klostermann, scientist at Fraunhofer FEP. “For this to work, however, the heat exchange with the storage material, which itself does not have good thermal conductivity, must also be designed efficiently. This can be achieved by aluminum layers, with which the material is coated. This ensures good heat transport and efficient heat transfer at the heat exchanger.” Besides the adsorption and desorption dynamics of the storage material, this is an essential performance aspect of a storage system and of great influence in its maximum as well as average specific heat output.

The granular storage material zeolite is vacuum-coated with aluminum in a bulk treatment. The requirement of good heat conduction presupposes a uniform, sufficiently thick coating. The researchers at Fraunhofer FEP are experimenting with layers more than 20 micrometers thick. These are realized with a technology that is otherwise used for web coating. Providing bulk coatings of a highly porous material with uniformly thick coatings in this way is therefore a major challenge, and Fraunhofer FEP’s developments to date are quite unique.

The process must be designed in such a way that the coatings do not hinder the mass transfer between the environment and the storage material; after all, the material must still be able to absorb and release water for the storage principle to work. Comparative adsorption curves of coated and uncoated material show that this mass transfer is not hindered by the applied coating.

Higher storage densities, smaller storage volumes – Developments for tomorrow

In particular, developers of novel storage materials with a focus on maximizing storage capacity are interested in the innovative coating developments of Fraunhofer FEP. Such new storage materials are mainly hybrid materials that are not manufactured on a large scale yet, as is the case with zeolites. In general, they are only produced in small quantities and are available in powder form. At Fraunhofer FEP, the challenge in the future will thus be to also treat these new materials in the metallization plant. Storage manufacturers are also hoping for these new classes of materials, which would give even greater weight to the aforementioned advantages over established water storage systems: higher storage density, smaller storage volumes.

There is also interest in another field of application: cooling with adsorption heat exchangers. In the future, these will replace some of the currently dominant compression chillers, whether stationary in combination with solar heat or in vehicle construction using waste heat from fuel cell drives. This will reduce the consumption of conventionally generated electrical energy and fossil fuels.

The researchers at Fraunhofer FEP are ready to adapt their technology and optimize coatings for the conditions of use in these exciting fields of application.

Fraunhofer FEP at V2021:

V 2021 - Vakuum & Plasma

12 – 13 October 2021

International Congress Center Dresden, Germany

www.efds.org/die-v

Industrial exhibition

Meet our colleagues and experts at Fraunhofer FEP booth no. 11

Program

12 October 2021

11:00 – 05:00 pm: Workshop Energy „Energy Turnaround by thin layers“

Program committee:

Dr. Claus Luber, Fraunhofer FEP; Dave Doerwald, IHI Hauzer, Venlo, NL

04:30 pm:

VO2-based thermochromic coatings on ultra-thin glass for smart energy savings in buildings with a high proportion of windows and glass facades

Jolanta Szelwicka, Fraunhofer FEP

Last modified:

Fraunhofer Institute for Electron Beam

Fraunhofer Institute for Electron Beam