Plasma-treated liquids have the potential to reduce the use of conventional cleaning and disinfecting agents.

Research at Fraunhofer FEP focuses currently on the relationships between cleaning and sanitizing effects as well as the shelf life.

Plasma-activated water (PAW), also called plasma-treated liquid (PTL), is known for its antimicrobial effect. Plasma-treated liquids are produced by introducing ionized gas from atmospheric pressure plasma sources into liquids, causing the reactive nitrogen and oxygen species generated by the plasma source to dissolve in the liquid or react with liquid components. Due to the variety of different reactive species, as well as the associated low pH and high redox potential, these liquids show an antimicrobial effect. The high reactivity of PTL additionally offers a potential for their use as cleaning agent. As part of our research activities, we are investigating the hygienic and the cleaning effect of PTL, as well as the suitability for combined use for cleaning and disinfection. Relationships between the effectiveness of PTL and the effect of the various reactive species are investigated to optimize the production technology and to allow an economically attractive and reproducible industrial use of PTL.

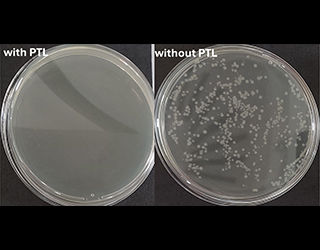

In our investigations, different model microorganisms are investigated to evaluate the sanitizing effect considering varying production conditions of PTL and environmental conditions. For example, a reduction of 99.9% was achieved on bacterial contamination with Escherichia coli after a short treatment time of only 5 minutes (see figure). One example of application for the investigation of the cleaning performance is the gentle removal of graphite residues on porous quartz surfaces.

In addition to the cleaning and sanitizing effect, the shelf life of PTL is an important point for industrial use. In initial investigations we were able to show that the liquids retain their reactivity for over 10 months.

Our further research focuses on the relationships between the plasma source and the properties of reactive species and their content in the generated PTL, as well as suitable monitoring methods for easy quantification of relevant reactive species enabling reproducible industrial implementation.

Fraunhofer Institute for Electron Beam

Fraunhofer Institute for Electron Beam