In the lighthouse project ElKaWe, six Fraunhofer Institutes have worked for several years on the development of electrocaloric heat pumps. The Fraunhofer FEP was involved with wetting-promoting surfaces on ceramic and polymer components.

Heat pumps are a key element of the energy revolution in Germany. They are currently the most commonly installed type of heating system, particularly for supplying newly built single-family homes. However, the classic compressor-based heat pump has a number of disadvantages, such as the use of refrigerants that are potentially harmful to the environment and health, as well as significant noise emissions.

For this reason, six Fraunhofer Institutes – IPM, IKTS, IAP, LBF, IAF and FEP – have joined forces in the lighthouse project ElKaWe to help a new technology achieve a breakthrough. These are electrocaloric heat pumps based on ceramic or polymer materials that can convert electrical energy directly into thermal energy.

In the underlying principle of heat transport, the working fluid periodically evaporates or condenses on the active surfaces in order to absorb or release heat. The faster this process takes place, the more efficient the pump is. However, especially for polymeric materials with their water-repellent (hydrophobic) surface, it is difficult to achieve rapid, complete wetting of the components with a thin film of liquid.

The breakthrough here came from a form of plasma treatment in vacuum, in which the surface of a polymer is bombarded with high-energy oxygen ions and a thin, open-pored layer of titanium-silicon oxide is deposited at the same time. The result is a nanostructure that enables full-surface wetting of the surface (superhydrophilicity). The effect is stable over the long term (months to years) and does not require reactivation.

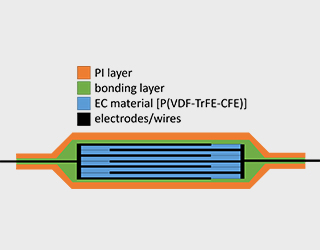

Since the limited thermal resistance of the electrocaloric material prohibits direct plasma treatment, an alternative approach was chosen: the structuring of a thermally resistant encapsulation film and the subsequent combination of this film with the electrocaloric material to form a usable component.

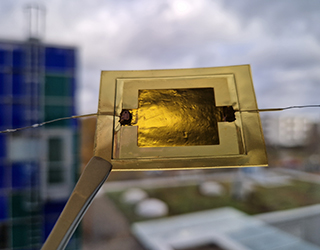

For use in polymer-based electrocaloric heat pumps, 12.5 µm thin polyimide films were treated at the Fraunhofer FEP using the process described and then laminated onto pre-processed multilayer stacks of electrocalorically active terpolymer at the Fraunhofer IAP. Tests carried out proved that the finished components functioned satisfactorily. These are currently being assembled into demonstrator assemblies, which will prove the performance of the resulting technology and serve to acquire new projects.

Fraunhofer Institute for Electron Beam

Fraunhofer Institute for Electron Beam