The LinTR learning laboratory for industrial parts cleaning at Fraunhofer closes a gap in further training in parts cleanliness, combines theory and practice and promotes interdisciplinary communication.

The importance of technical cleanliness in industrial production is increasing in more and more sectors. Cleaning processes are crucial in order to guarantee the quality requirements of a component. Nevertheless, there is a lack of practical training opportunities to learn and master complex process chains in relation to part cleanliness. To close this gap, the LinTR “Learning Lab for Industrial Parts Cleaning” was created. This innovative learning laboratory is designed to offer a flexible, modular concept that combines theoretical knowledge and practical skills, thus playing a key role in further training and professional qualification.

Supported by the Fraunhofer Academy, the Fraunhofer Institutes FEP, IWS, IVV and IPA are working on the development of the learning lab. Not only are the technical possibilities being expanded, but a new methodological and didactic concept is also being developed. This concept is based on typical process chains and can provide participants with a comprehensive understanding of industrial parts cleaning through practical training in various laboratories. A two-part, dismountable model component was developed for this purpose, which enables problem-based teaching through a combination of different geometries and standardized contamination.

Interdisciplinarity is a central element of the LinTR learning laboratory. Participants learn to understand the complex influences along a process chain and to recognize the importance of effective cooperation. This not only deepens their technical knowledge, but also trains their ability to solve problems in groups.

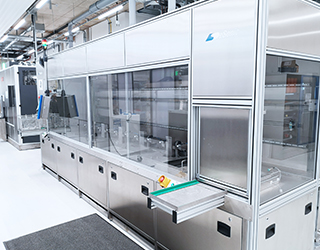

Another important milestone in the learning lab is the commissioning of our REDESO training cleaning system. This 6-chamber ultrasonic system for aqueous cleaning has a very wide range of adjustable process parameters, enabling practical cleaning tests to be carried out on a wide variety of components and production processes. In future, in addition to demonstrating cleaning effects, the system will also be used to analyze errors in the cleaning process, for example by deliberately setting some parameters unfavorably in order to enable training participants to systematically search for errors.

Overall, the LinTR learning laboratory will be established as an integral part of further training in the field of technical cleanliness at Fraunhofer and will thus make a decisive contribution to ensuring quality in industrial production.

Fraunhofer Institute for Electron Beam

Fraunhofer Institute for Electron Beam