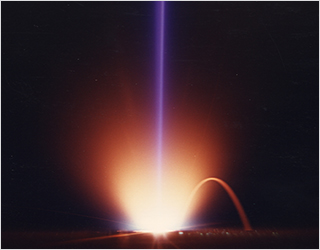

Electron beams are extremely versatile tools for materials processing, environmental technology, surface treatment, medical and technical imaging, process control, and analysis. They combine a wealth of physical, chemical, and biological effects with high energy efficiency, excellent precision, and technological flexibility.

In the field of electron beams, the surfaces of solid bodies such as metal strips and plates, 3D-shaped components and bulk materials, as well as textiles and biological tissues, are treated, functionalized, cleaned, joined or coated. Various physical and chemical vapor deposition (PVD/CVD) processes and electron beam welding in a vacuum are used, as well as cleaning techniques, electron beam treatment, and grafting at atmospheric pressure. On the other hand, biomedical liquids or waste water as well as industrial exhaust gases or chemical gases are cleaned, inactivated or subjected to specific conversion reactions using electron beams. To this end, not only processes but also customer-specific electron beam and plasma sources are developed and transferred. The aim is to provide our customers with application-ready complete solutions – technologies and systems from a single source.

Current projects focus on energy applications (coatings for batteries, hydrogen technologies, heat storage, photovoltaics), aviation (corrosion protection, thermal barriers on turbine components), chemical applications (power-to-chem processes), and environmental and life sciences (treatment of seeds, wastewater, and exhaust gases, stimulation of microbiological processes).

Fraunhofer Institute for Electron Beam

Fraunhofer Institute for Electron Beam